Most animal feed producers, especially the smaller ones, buy a pre-made blend of vitamins and trace minerals — the so-called vitamin and trace mineral premix, or just VTM premix. This is added at various levels in each feed, or a separate one is used for each different feed.

In general, it is advisable to buy two distinct premixes, one each for the vitamins and trace minerals because certain minerals tend to destroy certain vitamins when in close contact. Thus, if the trace mineral premix is bought as a separate entity, it merits considering mixing it a home, because with enough volume savings can be significant.

Trace mineral premixes, step by step

A homemade trace mineral premix makes more sense when large quantities of feed are farm-mixed, or if labor is inexpensive. Equipment for this job can be as sophisticated as a computerized micro-batch mixer or a simple hand-weight system. The following guidelines will ensure that all recommendations are considered when home-mixing:

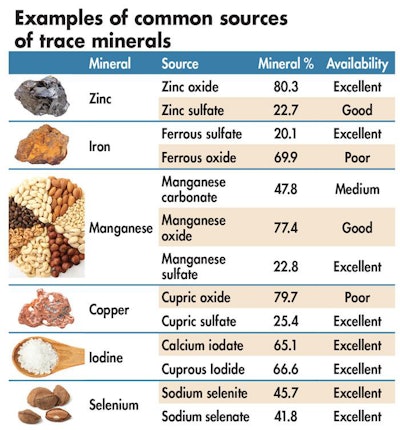

- Initially, a reliable, local supplier of highly-available trace mineral salts should be identified. The cost per gram of pure element (for example, iron, and not iron sulfate) is the final criterion for choosing the least cost product among salts supplying the same trace mineral (see below for availability complications).

- Afterwards, minimal and maximal inclusion rates must be pre-defined for all elements (iron, zinc, manganese, selenium, iodine). If a single inclusion rate will be used for all diets then an intermediate value should be set. Otherwise, the low inclusion rate can be used to formulate a premix suitable for finishing animals, whereas the high inclusion rate will be more suitable for young or high-producing animals.

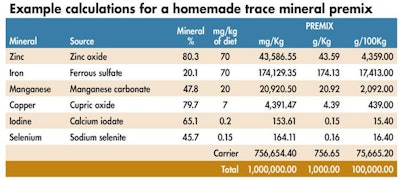

- The amount of the different salts per kilogram of premix can be found by dividing the required additions per kg of diet with the inclusion rate and multiplying the result by 1,000 times and dividing by the element’s concentration in the salt. For example, let us suppose that ferrous sulfate (20.1 percent iron) is the salt of choice to provide iron at 70 mg per kg of diet and the inclusion rate for the premix is set at 2 kg per metric ton (MT). Thus, the quantity of ferrous sulfate per kg of premix can be calculated as (70/2)x1,000/0.201=174,129 mg or about 175 g of ferrous sulfate per kg of premix.

- Usually, grower and starter diets need additions as high as 150 percent and 200 percent of finisher inclusion rate, respectively. Small excesses are not harmful but deficiencies must be compensated by increasing inclusion rates for these diets during premix design.

- Finally, a suitable carrier (corn gluten feed, wheat middlings, ground rice hulls or even just corn meal) should be used to make up the difference of the salts up to 1 kg.

- At least 100 kg of premix should be prepared at one time in a small mixer (not the one used to mix normal feed) to ensure all ingredients are mixed thoroughly.

Mineral availability

It is common practice to consider all minerals as fully available to the animal or, more correctly, ignore any differences in their availability. Reality is different, however; not all mineral salts offer the same availability (see table, Examples of common sources of trace minerals). Trace minerals are found as ores or industrial by-products in the form of salts with variable availability but usually exceptional pure element stability.

Although we have rather reliable values for mineral availability, we currently lack sufficient data to relate these values with actual requirements of animals on an available basis.

Although we do have rather reliable values for mineral availability, mostly for poultry, we currently lack sufficient data to relate these values with actual requirements of animals on an available basis. To this end, it is common practice to use only salts of good to excellent availability, and quite often to use generous safety margins in mineral specifications. All these are possible due to the low cost of mineral salts, but for environmental reasons, some degree of sophistication is required to reduce excesses of zinc and copper.

Organic minerals

Certain organic minerals are more bioavailable than their inorganic counterparts, but this is not a general theme as there are certain inorganic salts that are highly available as well. When using organic minerals to provide trace minerals for nutritional purposes, their availability can be considered as a plus. It is possible to lower initial premix specifications or determine availability levels from inorganic salts before attempting to incorporate organic minerals. In most circumstances, the cost per unit available trace mineral tends to be more expensive than its inorganic equivalent.

Density and inclusion rates

Premix concentration in pure nutrients is of little value unless this information is combined with inclusion rates to give final addition levels per kilogram of complete feed. This last single characteristic is of paramount interest since it determines both product quality and price.

Usually, inclusion rates range from as little as 1 kg to as much as 5 kg per metric ton of complete feed. Levels below 1 kg should be avoided because they do not support optimum blending of the premix with the rest of the raw materials. At the other end, levels above 5 kg tend to occupy too much space especially in sensitive and often high-density diets. Plus, logistics for high-inclusion rate premixes only add to the cost, especially in an exercise undertaken to reduce costs.

Learn more: Stop wasting vitamins, trace minerals in animal feeds

Generally, a premix at 2 kg per MT is used in all feeds when a common addition level for all diets is practiced. When variable rates are employed, 1 to 2 kg per MT is sufficient for finishing diets, whereas up to 4 to 5 kg per MT are used for starter and breeder diets. In general, with a home-mixed premix there is considerable room for flexibility that can be built in during the design phase.

Vitamins

It is not generally recommended, even for small-scale feed plants, to buy individual vitamins and blend them. Certain vitamins are particularly unstable or sensitive and require special storage and handling. Plus, most are extremely expensive and the required stock will tie up considerable capital. And, in most cases, a computerized micro-batch system is required for satisfactory results. Vitamin premixes should be bought from a reliable, well-known supplier who supports his or her products with adequate information. Of course, home-mixing is not impossible, but it does require considerably more sophistication than mixing mineral salts.