Immunoglobulins are widely used in piglet feeds as they form an integral part of dairy, blood and egg products — all specialty ingredients used at high levels in such sensitive feeds. Lately, the use of immunoglobulins through plasma in broiler diets has resulted in the creation of super-performance prestarters, the same as with piglet creep feeds. Before one decides which product to use, it is best to understand the functional role of these proteins as well as the differences arising from their source material. Below is but a brief explanation on the most critical aspects to help nutritionists and purchasers decide what is best for their feeds.

1. Immunoglobulins are natural compounds

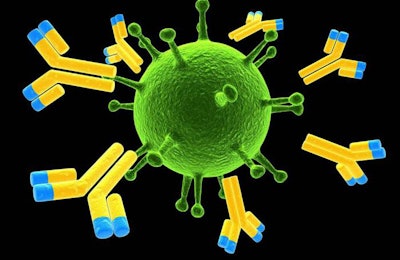

Nobody doubts the all-natural origin of immunoglobulins. Mammals and birds produce immunoglobulins as part of their immune system. These globular proteins of the immune system are also known as antibodies. They are produced as a result of a bacterial, yeast or viral infection, and also as an autoimmune hyper-sensitivity reaction, such as against the storage proteins on soybeans. In essence, immunoglobulins are as natural as milk, blood and eggs. Perhaps, some sources offer a concentrated form of immunoglobulins (animal plasma), whereas others a designed pathogen-specific profile (hyper-immunized eggs), but still we are talking about a product sourced from animals without anything synthetic about it.

2. Immunoglobulins are target-specific agents

Immunoglobulins are very expensive for the organism to create; as such, they belong to the last-defense arsenal, when all other antigen-defeating measures have failed. They are very expensive to manufacture because the organism makes them very specific. They target the exact strain of pathogen that infected the organism. This has a dual implication. First, if the source of immunoglobulins used as a supplement does not contain antibodies against which the original animal had developed immunity against, then this product will not work. For example, say animal plasma originates from animals never exposed to E. coli F18. Animal plasma from such animals will contain no such immunoglobulins. If this plasma is fed to piglets (or broilers) suffering from E. coli F18, there will be no real benefit to them. Conversely, if egg powder from hens hyper-immunized against E. coli F18 is fed to piglets suffering from E. coli K88, then again it will not be the same. This is why one needs to make sure the selected source contains the right immunoglobulins for the right job.

3. Immunoglobulins have multiples modes of action

Immunoglobulins do not kill pathogens by themselves; they do so indirectly. First, they attach themselves to the pathogen, which they recognize with an extremely high efficiency. This process causes two troubles for the invader. First, its ability to attach to the gut epithelium and colonize is limited as the available attachment tools are blocked by the immunoglobulins. Thus, pathogens are largely excreted to the environment. Second, immunoglobulins act as red alert flags, signifying to other components of the immune system that the "tagged" pathogen is to be eliminated immediately, making pathogen killing a very rapid and efficient process. Thus, once immunoglobulins are produced by the animal, or fed as a supplement at the right dosage, pathogen elimination is a very rapid and efficient process.

4. Types of different immunoglobulins

Mammals produce immunoglobulins G (IgG), whereas birds produce immunoglobulins Y (IgY). These are the major immunoglobulins circulating in blood. Mature milk (not colostrum) contains immunoglobulins A (IgA). Starting from the last one, IgA are very weak and largely aspecific immunoglobulins working at the gut epithelium level. In contrast, IgG and IgY are pathogen-specific immunoglobulins found in blood. Birds have a more powerful type of immunoglobulins: IgY binds with higher strength and with better efficiency than IgG, because the egg is a smaller "package" than milk — the only way to pass immunoglobulins from mother to offspring.

5. Sources of immunoglobulins

Blood plasma is the primary source of IgG, although bovine colostrum is also used for the same purpose. Both are rather expensive, albeit effective, ingredients, with colostrum being so expensive that it is used rarely, and then only in high-quality milk replacers. Bovine plasma is as good as porcine plasma, and this indicates the cross-species ability of immunoglobulins to control pathogens. Eggs from hens hyper-immunized against specific piglet diseases are the source of "designer" IgY, which are less expensive than IgG, but they lack the protein (nutrient, amino acids) fraction of plasma. All sources are equally effective, assuming premium quality and safety, and at the end it comes down to cost of use.

6. Quality aspects (source, specificity, titer)

Quality in immunoglobulins sources is as important as in any other ingredient. Here, however, we have a few extra quality aspects that need to be considered. In plasma, the distinction between bovine and porcine, the guaranteed level of IgG, and the minimum level of crude protein as among those quality criteria important for making a business decision. In egg IgY sources, it is important to consider the pathogen-specific IgY profile and the way this product is produced. For example, if IgY are the result of a cocktail-type vaccine, then the resulting IgY profile will be a random cocktail as well. In contrast, a controlled production will ensure stable titers in every batch.

Conclusion

We have been using immunoglobulins since we first fed dairy products to young pigs. Today, we have increased the sophistication of this technology, but still we lack much in-depth knowledge. For example, we don’t know what is the requirement for IgG and/or IgY, and of course the conversion factor between the two. Nevertheless, we have enough background information and experiences to make an informed decision when it comes to selecting and purchasing the right immunoglobulin source for the right job.