I recall a time when feed formulation, for me, was a world full of wonderment and perplexity. I was an undergraduate in animal science, and I was hopelessly trying to find books about how to formulate programs. At that time, MS-DOS was reigning, and feed formulation software was more valuable than gold — at least this is what some of my mentors led me to believe. Undaunted, however, I built my own feed formulation program using an IBM algorithm that I found at the university’s library and Fortran C (a software-developing language). Lamentably, I no longer have these things in my possession, but I do recall spending countless hours formulating diets for pigs and poultry.

Still, we don’t have any serious books explaining feed formulation strategies to students, and what exists is mostly the basics in chapters buried in some older books that are hard to access anymore. It is easier to find a feed formulation software package. Some are free, but they are riddled with problems and are mostly unreliable; the rest are prohibitively expensive. I will applaud the first company who creates a student package affordable by those who want to learn — their future clients. Of course, there is still MS Excel, which has now incorporated the Solver add-on feature that enables resolution of complex problems like least-cost formulation. To my puzzlement, I am still trying to find an affordable piece of software to replace my trusted spreadsheet, but this is another story.

Nevertheless, it is not enough to have a good feed formulation computer program and someone to operate it. In addition to these, the right parameters and values should be used so that the true least-cost formulation is produced. Entering the wrong data will only result in the wrong answer, and when it comes to feed, this is a costly answer as animals will either be overfed or underfed; in either case at a loss of profitability. Working with a qualified nutritionist to establish the right dietary specifications for the different feeds and, at the same time, determine the best available ingredient nutrient database, should be considered an important investment in feed mills that produce finished-complete feeds for animals. Unfortunately, this is seldom the case, resulting in gross loss of profit potential.

As an introduction to the topic, and to the aid of any students reading this article, I offer a brief summary of the main points to ensure feed is formulated based on the most modern and economic ways.

Energy

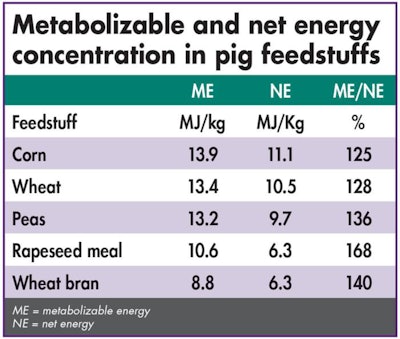

Most feeds for monogastric animals are formulated using the metabolizable energy (ME) system. While this is a perfectly good system, it suffers severely when formulas depart from the common cereals (corn, wheat) and vegetable protein sources (soybean meal). The reason is because with the ME system, by-products rich in fiber or protein are not evaluated correctly. This issue is resolved by the net energy (NE) system.

In the table, this problem is illustrated clearly. It is obvious that the conversion of ME to NE is similar when it comes to common cereals, such as corn and wheat, and thus it makes little difference which system is used in formulating feeds based on these ingredients. When it comes to less conventional ingredients, however, the disparity is very large. This is the strongest in the case of rapeseed, which in terms of energy, is not better than wheat bran.

Another benefit of the NE system is that it allows for separate energy values to be used in growing versus breeding animals. The ME system ignores the energy contribution from fermentation taking place in the large intestine, but the NE system correctly attributes a better NE value when ingredients are destined for use in breeding animals. In other words, feeds for breeders formulated on NE tend to be less expensive.

All of the above are now clear-cut knowledge for pig nutritionists, and robust, reliable and readily available NE databases are commonplace. When it comes to poultry, we are now in the infancy of the NE system, but it still has to prove it offers a significant savings over the very well-known ME system.

Protein

Protein, and consequently amino acids, are the second most expensive nutrients in feeds for both poultry and pigs, following energy. Thus, using the correct form to describe their presence in feed is of paramount importance in creating a least-cost formula. When using total amino acids, a minimum in crude protein concentration is required to ensure all amino acids are present in sufficient quantities. However, by using digestible amino acids, formulas do not have to have a protein minimum, assuming all essential amino acids are sufficiently covered through formulation. This translates again in feed formulated at the least possible cost, taking into advantage cheaper sources of protein, and, quite often, feed-grade amino acids that can now be used at greater amounts.

It should be emphasized here that there is a plethora of published values for digestible amino acids, some of which are calculated values and others based on scientific trials. Care should be taken to ensure the correct set of tables is used because a slight bias in one direction or another might erase any benefits from this exercise. Some differences do exist among the correct form of digestible amino acids (true or apparent, and ileum or total) for pigs and poultry.

Phosphorus

This is the third most expensive nutrient. Total phosphorus, as a way of describing the phosphorus concentration in feed, is very inaccurate and leads to over-formulation. For example, monogastric animals are able to utilize only 1/3 of total phosphorus in cereals; in contrast, phosphorus in animal protein sources is utilized up to 2/3 of the total. The intermediate term "available phosphorus," where an ingredient’s phosphorus use is indexed against a standard source (sodium phosphate), is an acceptable form for poultry. Nevertheless, it has been surpassed by the most accurate term "digestible phosphorus," which is now available for pigs, but not for poultry. The two values are close but not identical, and one should take care which database is used for which species. It follows that requirements should be expressed in comparable terms.

Vitamins and trace minerals

This is a sensitive area, where small changes can make big savings in feed cost when large operations are considered. Here it is not so much the form of describing the presence of its nutrient, but rather its actual concentration. Nevertheless, when organic forms of trace minerals are being used, their enhanced availability should be reflected in lowering overall feed specifications. The availability of vitamins is quite different among certain sources, and this too should be taken into account when these premixes are designed. One clear example is sufficient to illustrate the issue. Copper oxide is totally unavailable to monogastric animals, yet it is being used (very infrequently now) as part of a vitamin and trace mineral premix, mainly because it is the cheapest source of copper. Naturally, animals do not suffer from copper deficiency because copper provided by natural ingredients (corn, wheat, soybean meal, etc.) is usually sufficient and quite often above their requirements.

Fiber

Fiber is undesirable in most formulas because it reduces energy density and nutrient digestibility. However, functional fibers are beneficial in improving animal gastrointestinal health. Up to this time, there has not been an agreement on which is the best term to describe the fiber fraction in feed. Therefore, the term crude fiber continues to be the base on which ingredients are evaluated in commercial feed mills. Other forms, more complex, exist, but values for many ingredients are yet to be determined. Most importantly, fiber dietary specifications (minimum and maximum values) for pig and poultry formulas, other than those of crude fiber are very difficult to encounter in publicly available literature. All these imply that the term crude fiber is the best option for the present time, when all things practical are considered. Quite the opposite is true in feed formulation practices for ruminants where using the more advanced fiber terms is the norm and crude fiber is now an anachronism.

Nutrient specification databases

Table values such as those provided by National Research Council (NRC) and other national bodies of research and development are quite common in setting target values for the above nutrients. While these examples provide an excellent starting base, modifications are required to ensure specifications meet actual animal needs. Because of the generic form of such table values, not all cases can be covered. It is actual commercial animal performance that should be used as a guideline in setting final formula dietary specifications. This ensures minimal feed cost and maximal animal performance. This goal can be achieved through trial-and-error (or else, via nutrient-challenge trials), or by employing the use of a growth model. Most commercial nutritionists have tested a multitude of databases and have settled (or not!) on what they consider most reliable.

Learn more about managing nutrient variability in feed formulations