Estonian company Pro Grupp Invest OÜ has recently opened a large feed mill in the Kantküla village of the Torma vald in Jõgevamaa, Estonia. With the capacity to produce 120,000 metric tons of animal feed per year, the facility promises to be one of the largest suppliers of compound feed production for pigs and cattle in the Baltic States. But, it is no secret that the project was commissioned during hard times when the Estonian meat and dairy industries are hampered by numerous factors.

Hard times for Estonia agriculture

In recent years the demand for feed production in Baltic States has faced turbulence due to several factors, including Russian embargo from August 2014.

“I think Russian embargo has [had a negative] impact, but at the moment, [the] agricultural sector in Estonia has more serious issues than embargo,” says company representative, Tanel Kurvits. “Firstly, the milk price is very low globally; secondly, milk producers have to pay fee for exceeding the milk quota. Thirdly, pig farms were affected by African swine fever with over 20,000 pigs culled and zone three limitations [quarantine zones with prohibiting on exporting pork] still in force.”

For instance, in the resolution of the fourth congress of Estonian Union of Farmers, it is said that next year, the livestock industry in the country will need EUR21 million (USD23 million) of direct support. The resolution says that currently the crisis in the dairy and pig industries is at its peak and numerous manufacturers are on the verge of extinction.

According to the estimation of an industry representative, the tough situation may soon result in bankruptcy for one out of 10 dairy farms.

The resolution states: “Mostly distressed Estonia farms should receive urgent financial assistance from the state until the end of the year. Otherwise we would not talk about the elimination of certain pig or dairy farms, but about the extinction of the entire sectors of the national economy.”

Defying odds

Despite tough times, representatives of Pro Grupp Invest OÜ believe that the situation is not as bad as it seems because the company has well-established contacts with major clients so the feed production of the Kantküla feed mill will be in demand.

“This year’s crop harvest had new records, but this helps a little because the crop prices are also very low,” says Kurvits. “Many pig and dairy farms were closed or bankrupt. The Estonian government has provided some actions for supporting the sector, but this is slight comparing to other countries and clearly too late. For us, we have many possible clients, but it is hard to find clients who are able to pay and able to do it correctly. But we have found strong partners, we are improving our products cooperation with them and this is win-win situation.”

About the mill

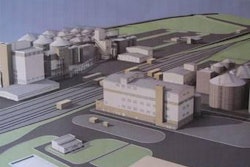

The Kantküla facility officially opened its doors in 2015, but in 2014 the company brought in revenue from the drying and selling several crops.The total investment in the project amounted to EUR8.5 million (USD9.3 million).

The complex consists of a plant with a warehouse, an office unit, bin storage for 12,000 metric tons of feed, and a grain drying and sorting station.

“The technology [used in the mill] comes from well-known European manufacturers Petkus Technologie GmbH and Ottevanger/Wynveen,” explains the manager of the feed mill, Leonid Dulub. “The feed plant is compact and includes all necessary top-tech equipment for the production of quality feed.”

More than 200 different devices have been installed, Dulub says, so a single operator can manage the complex, controlling the processes at the computer screens, and all work is done in specially created computer programs.

Mapri LLC acted as the construction contractors; the project was designed by AS Viljandi Metall; and Agriland LLC supplied the equipment.

The new feed mill of Pro Grupp will primarily specialize on the production of feed for pig and cattle, including young cattle and calves.

“[We choose the mills geographical location] because the location is in the middle of Estonia and also near to the biggest crop fields and possible clients,” explains Kurvits, adding that the production range will be wide and, in the future, the facility also may produce poultry feed and feed for fish.

“We produce a complete range of feed for pigs, including the species for sows, piglets and pre-slaughter pigs,” Dulub adds. “In the near future we plan to start the production of feed for chickens. We are also manufacturing medicated feed. Kantküla feed mill produces the feed, containing many different ingredients, including molasses, which ultimately improves the appetite of animals and increases milk production of dairy herd.”

Pro Grupp makes feed based on the formulations of the Dutch partner De Heus.

Outside opportunities

Kurvits explains that the Kantküla feed mill will probably supply some part of production abroad and Pro Grupp is currently is considering such possibility. However, he didn’t disclose any details on this issue.

Representatives of the feed mill also pointed out that the use of this production would be cost-effective, which is especially crucial in the current economic situation in the industry.

“We are working on the cooperation of farmers and livestock producers in the long term, and it is beneficial for both sides,” says Dulub. “In general, it is important that pig farmers are interested in spending less money on the production of one kilo of meat, and for dairy breeders, it is important that the production of a liter of milk would cost a minimum of feed, whilst guaranteeing healthy production. Pro Grupp understands the dairy producers and looks forward to partnering with the farmers, who want to save money.”