The case has been made often regarding the futility of keeping crude fiber as anything but an index of historical appeal when it comes to define fiber quantity and quality in a feed or ingredient. Ruminant nutrition scientists have developed a new fiber system based on two better chemical analytical values, namely acid-detergent fiber (ADF) and neutral-detergent fiber (NDF), but it is of rare if any use for monogastric animals.

Terms like water-holding capacity, solubility and fermentability have emerged for poultry and pig diets, and there have been several, but not enough, scientific reports trying to establish a working method on how to use them in everyday formulation practice. Results remain frustrating, if only because we lack two basic things:

- A comprehensive database of all ingredients describing their concentration in these new fiber values. Such an undertaking is not impossible, but it is rather expensive, given the plethora of fibers within each ingredient.

- A set of values to be used as feed specifications during formulation that will relate ingredient concentration in each fiber value with feed final figures.

Fiber sources and their values

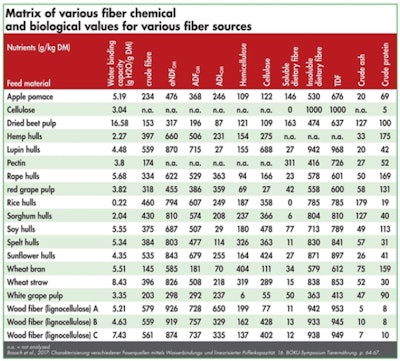

An interesting array of fiber values for a number of fiber sources can be seen in the table. It is lamentable that this table, which has just been published, does not include other ingredients as well, but given the complexity of such research, it remains an excellent start.

Modern fiber thinking is now beyond chemical analyses as we focus more on biological values.

One most notable aspect that fiber enthusiasts will soon observe by studying these data and any such similar information is that there is no strong correlation between any of the values presented in this table. There are some patterns, explained by similar forms of fiber among different ingredients, but the breadth of differences even among the same family of fibers, and the number of such families, makes their combination in each ingredient almost unique — a fiber signature!

Of high note are three ingredients with high solubility, namely apple pomace, dried sugar beet pulp and pure pectin. All are rich in pectin, yet only one of them, sugar beet pulp, has a water-holding capacity that can be attributed to its high pectin level.

Water-holding capacity

This is a most confusing index of fiber quality because scientists have not determined yet how to incorporate it into feed formulation specifications. First, in animals prone to bacterial diarrheas and fed diets without antibiotics, we require a low-moisture environment in the upper gastrointestinal tract — otherwise excessive bacterial growth may promote pathogenic strains to the animal’s detriment. But, a drier digesta will result most likely in reduced penetration by digestive enzymes, leading to reduced nutrient digesta. So, these two aspects work against each other, and one cannot have both in the same feed formulation design.

Finally, we must ensure water is released in the large intestine for reabsorption. Otherwise, we will have incidents of wet litter, leaky diarrhea (non-pathogenic), dirty eggs, loose stool, etc. Thus, diets must be designed having specific goals and always taking into account the hygiene levels of each farm before employing the right tools to control digesta moisture levels at each site of the gastrointestinal tract.

Chemical values

The chemical value of renown remains crude fiber, but it is now antiquated as we understand it includes but a small fraction of functional fibers. For example, a feed high in pectins or highly soluble hemicelluloses is not likely to figure high in terms of crude fiber as these fractions are not caught up easily during crude fiber analysis.

Learn more: 6 fiber insights for formulating livestock feed

Other chemical analyses appear more comprehensive, but they remain largely irrelevant to monogastric nutrition. Such are NDF and ADF analyses that were developed to cater for ruminant fiber nutrition. Even though these values will not change from species to species, like crude fiber, we have virtually nil data regarding monogastrics. Even, then, modern fiber thinking is now beyond chemical analyses as we focus more on biological values. This is not to say chemical analyses are obsolete, but rather that they have become a tool in establishing biological values that correspond to each species.

Biological values

In monogastric animal nutrition, we are currently describing fiber as soluble versus non-soluble (for the part of the gut that includes the stomach and most of the small intestine), and fermentable versus non fermentable (for the part that includes the last part of the small intestine and all of large intestine). It is a common error to believe that all soluble (or non-soluble) fiber is equally fermentable (or non-fermentable).

Today, we know that this is just not true, at least in absolute terms when precision is required. It should be noted here that in order to determine the solubility and fermentability of an ingredient, we require live animal tests, something that adds to the delay by which new data emerge. In-vitro (lab) tests will eventually become commonplace, but these will always remain more expensive than chemical analyses, and, of course, never as accurate as in-vivo (live animal) tests. Thus, research focus remains on those species and feeds that can provide a quick return on investment — such as feeds for young animals, those raised with antibiotic-free diets under challenging conditions and animals already suffering from gut health problems. At this moment, there is not a concrete set of feed specifications for these biological values, and, as such, each nutritionist has to use empirical evidence, at best.

Additive values

Whereas we know from research, experience and chemistry that chemical values such as crude fiber are additive, we remain uncertain whether the same holds true for biological values. For example, if we blend two ingredients with different crude fiber concentration, we know that the crude fiber concentration of the mix will be the weighted average of the two. Whether this simple principle, which is the cornerstone of least-cost feed formulation, can also be applied to fiber solubility and fermentability remains to be seen. In addition, we must also quantify the effects of various exogenous enzymes on solubility and fermentability, opening a whole new area of interesting research!

Sugar beet pulp

The extraction of juice from sugar beets leaves a pulp with 10 to 15 percent dry matter that is frequently used in the vicinity of the sugar factory as fodder for ruminants. If dried, it becomes a more useful commodity as it can a substantial source of nutrients, containing 10 percent crude protein, about 10 percent sugar and a substantial array of fibers. The latter include mainly celluloses, hemicelluloses and pectins.

Pectin concentration can reach up to 20 percent of dried sugar beet pulp, making it a most interesting fiber. It is often speculated that the high swelling (water holding capacity) exhibited by dried sugar beet pulp is mostly due to its high pectin concentration. A close look at the table presented in this article will demonstrate that pure pectin (from apples) is not as strong as in holding water as sugar beet pulp fibers. This is perhaps due to the different pectins among the two sources, or an interaction of different fibers within sugar beet pulp. At any rate, dried sugar beet pulp remains the strongest raw material in terms of water holding capacity.

Wood fiber (lignocellulose)

A most unlikely source of fiber, wood fiber (lignocellulose) has become almost a commodity nowadays. It is mostly, but not exclusively, made of celluloses, hemicelluloses and lignin. This ingredient is highly hydroscopic (absorbs water), but not to the extent of sugar beet pulp. It also offers other fibers, as well, and most importantly a variety of phenolic compounds that can exert antioxidant activity. The most pronounced benefit of this novel source of fiber is that it is a wholesome (not purified), yet concentrated source of functional fibers. Thus, it is preferred by premix manufacturers who are always pressed for space in their product formulations.

Take-home message

Today, we have breached the wall of crude fiber that kept everything ensconced in a black box. Ruminants led the way, but monogastrics have not benefited from such knowledge as the antibiotic-free era have forced nutrition thinking to delve into biological aspects. We have done most of the qualitative work, that enabled us to create a modus operandi. What we now need is a final push to obtain quantitative data that will transform all these data into practical feed formulation techniques.

One notable aspect that fiber enthusiasts will soon observe by studying these data and any such similar information is that there is no strong correlation between any of the values presented in this table.