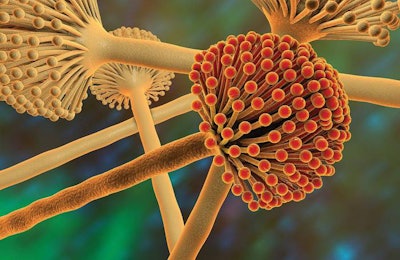

During harvest of 2015, the weather presented perfect conditions for the growth of certain molds and mycotoxins.

According to Alltech’s harvest analysis report, of the 100 corn samples submitted from across the United States and Canada, 96 percent of samples contain one or more mycotoxins. The annual survey, which tracks the occurrences of mycotoxins throughout North America, also concludes the 2015 corn crop contains an average of 3.1 mycotoxins.

The most prevalent mycotoxin group found throughout North America for 2015 corn was fumonisins, which were measured in more than 70 percent of samples, as well as the Type B trichothecenes and fusaric acid, found in more than 55 percent of corn samples. The concentrations of these mycotoxin groups were quite variable, ranging from lower to very high levels of contamination.

Additionally, although measured at a lower occurrence in the 2015 harvest, the storage mycotoxins from the other Penicillium mycotoxins group have been measured in significant levels. This may be of concern for feed millers storing corn for long periods of time because the presence of these molds and mycotoxins have already been observed and have a risk of increasing if grains are not stored properly.

Fumonisins were observed more frequently along the East Coast, although all mycotoxin groups have been detected and revealed a frequent occurrence of the Type B trichothecenes and fusaric acid. In the Midwest, there is an even distribution of occurrence among these three mycotoxin groups.

Why be concerned?

As the Food Safety Modernization Act (FSMA) went into effect, feed mills were given one to three years (depending on size) to complete full implementation. The legislation requires feed mills to have a written food safety plan, a hazard analysis with preventive controls, frequent monitoring and verification procedures, and a clear corrective action and recall plan.

Feed mills will be held accountable for monitoring their facilities and controlling safety hazards. When looking into animal health risks, mycotoxins are on the top of the list, thus requiring feed mill managers to fully comprehend the risks associated. It will necessitate implementing programs to minimize those risks, carrying out better sampling and collection of incoming raw materials, as well as undergoing frequent mycotoxin testing programs that could either be quick-test technologies or partnering with high-precision labs, or even a combination of the two. After testing, it is recommended to establish a clear maintenance and cleaning program for equipment and the area outside the milling system, reducing built-up material that could harbor bacteria and mold.

Written safety plans for each mill are now required to identify preventive controls, providing assurances that mycotoxins and other hazards are minimized or prevented.

Mycotoxins’ impact on animal health, producer profitability

Once mycotoxins are present in the grains, either from the field or from storage, they can remain in feed and become harmful to the animals consuming the contaminated material.

In pigs, the mycotoxins measured in this year’s harvest may cause a decrease in feed intake and more digestive disorders along with intestinal damage and poor feed efficiency. These symptoms may also lead to an increase in intestinal pathogen colonization and a suppressed immune system. Additionally, mycotoxins such as fumonisins can have a strong impact on the internal organs of the pig. Fumonisins are linked to the occurrence of pulmonary edema, the accumulation of fluid in the lungs.

With these negative effects of mycotoxins, pigs may have losses in performance, which would affect producer profitability. In fact, based on the average risk from the 2015 corn harvest analysis results, it is estimated that growing and finishing pigs may lose an average 24 grams/pig in average daily gain, which in turn could relate to a loss in carcass weight. As a result, carcass profit may decrease by an average of $3.09 per carcass.

Poultry are somewhat more tolerant than pigs to the mycotoxins measured in this year’s harvest. However, birds can still be impacted by chronic mycotoxin intake. Poultry may show a decrease in feed intake along with increased digestive disorders and an escalation in intestinal pathogens. The immune system can be impacted as well due to the presence of mycotoxins. Although these effects may not be observed on a daily basis, birds may still be impacted over time.

Based on the average risk from the 2015 corn harvest analysis results, it is estimated that broilers may lose an average of three grams per bird in average daily gain, which in turn could relate to a loss in carcass weight. Again, this loss in weight can relate to a loss in carcass profit by an average of $0.21 per bird. Layers can also be affected by mycotoxins. In this case, it is estimated that over 62 weeks they may produce four eggs less per hen. This can add up to a significant profit loss over time.

What can feed mills do to reduce mycotoxin risk?

Analyzing grains coming into the mill is critical to controlling the total mycotoxin risk at the mill. If possible, highly contaminated grains may be segregated to be included in the ration at a lower rate and/or fed to less sensitive species/ages.

Properly storing grains is important to overall long-term quality. Grains should be dried to under 14 percent moisture, and should be stored in silos that are free of holes or moisture entry.

Cleaning of the feed mill and storage facilities should be completed regularly. Crusts can build up on mill equipment and harbor storage molds and mycotoxins. These may later break off to further contaminate feed.

A successful mycotoxin management program goes beyond sampling and rejection of specific ingredients. The feed mill manager must establish an extensive quality assurance program, train employees, and execute the program across all feed manufacturing and delivery processes. Feed mill managers must also educate their customers and growers in order to help prevent mold growth and mycotoxin production in the bin on farm.

Safe feed for animals is the responsibility of all employees at the feed mill. The production of high-quality, safe feed is a collective effort, which requires the commitment of top management, the feed mill manager and employees.