The pig industry is going through a prolonged rough patch. Feed is expensive, bank credit is hard to find, meat prices are always on the low side and regulations keep proliferating, asking for more investments in new facilities and management practices. Difficult times call for drastic measures, and this is the perfect time to think about serious savings on feed costs by implementing an extreme re-evaluation of every farm’s nutrition program.

Part of this exercise will be to revisit the principles of formulating pig feeds. It’s not enough to have a formulation computer program and someone to operate it. In addition to these very essential aspects, the right parameters and values should be used so that the true least-cost formulation is produced. And, these parameters are not easy to identify without the use of a qualified and very experienced nutritionist. Here is a brief summary of the main points to ensuring feed is being formulated based on the most modern and economic methods.Use proper energy systems

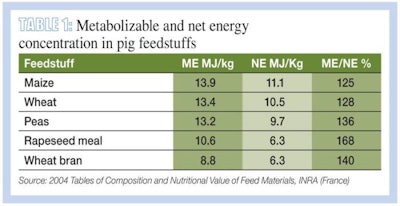

In most parts of the world, pig feeds are still formulated using the Metabolizable Energy (ME) system. But, for example, in Britain, the digestible energy system is still favored by many, whereas in Denmark, a largely empirical local Feed Unit system is used. While these can all be perfectly good systems, they all suffer severely when formulas depart from common cereals (maize) and well-known vegetable protein sources (soybean meal). The reason is because with these older systems, byproducts rich in fiber or protein are not evaluated correctly. This issue has been resolved, however, by the Net Energy (NE) system, which is widely known but infrequently used.

Let’s examine the data in Table 1. It is obvious that the conversion of ME to NE is similar when it comes to common cereals, such as maize and wheat, and thus it makes little difference which system is used in formulating feeds based on these ingredients. When it comes to less conventional ingredients, however, the disparity is very large. This is the strongest in the case of rapeseed, which in terms of energy is not better than wheat bran. Another benefit of the NE system is that it allows for separate energy values to be used in growing pigs versus breeding animals (sows and boars). The ME system ignores the energy contribution from fermentation taking place in the large intestine, but the NE system correctly attributes a better NE value when ingredients are destined for use in breeding animals. In other words, feeds for sows formulated on NE tend to be less expensive.Least-cost protein usage

Following energy, protein and, consequently, amino acids are the second most expensive nutrients in a pig feed. Thus, using the correct form to describe their presence in feed is of paramount importance in creating a least-cost formula. When using Total Amino Acids, a minimum in crude protein concentration is required to ensure all amino acids are present in sufficient quantities. However, by using Digestible Amino Acids (Standardized True Ileal Digestibility values are strongly recommended), formulas do not have to have a protein minimum, assuming all essential amino acids are sufficiently covered through formulation. This translates again in feed formulated at the least possible cost, taking into advantage cheaper sources of protein, and quite often synthetic amino acids.

It should be emphasized here that there is a plethora of published values for Digestible Amino Acids, some of which are calculated values and others based on scientific trials. Care should be taken to ensure the correct set of tables is used as a slight bias in one or other direction might erase any benefits from this exercise.Lactose alternatives

Lactose is important in piglet feeds, but it is not just lactose that piglets require to thrive on. They can use other simple sugars with equal efficiency. It is thus the term “lactose equivalents” must be used. Thus, ingredients containing simple sugars can now contribute to the need for “lactose equivalents,” often at reduced cost. Such ingredients include sucrose (table sugar), fructose, high-fructose corn syrup, dextrose and malto-dextrins. Cooked cereals perhaps are able to partially cover this need as well, but research is lacking to this aspect.

‘Digestible phosphorus’ > total phosphorus

This is the third most expensive nutrient. Total phosphorus, as a way of describing the phosphorus concentration in feed, is very inaccurate and leads to over formulation.

For example, pigs are able to utilize only one-third of total phosphorus in cereals, yet in animal protein sources, up to two-thirds of total phosphorus is being used. The intermediate term “available phosphorus,” where an ingredient’s phosphorus use was indexed against a standard source (sodium phosphate), is an acceptable form, and it is widely used by poultry nutritionists. Nevertheless, it has been surpassed by the most accurate term “Digestible Phosphorus,” that requires very little further explanation. This term provides a clearer picture of the amount of phosphorus available to the animal for productive purposes. Of course, we could move on to metabolizable and net phosphorus, but at the moment, there is no such need in the industry.Vitamins & trace minerals

Small changes that make big savings in feed cost is an interesting area of nutrition. Here, it is not so much the form of describing the presence of its nutrient, but rather its actual concentration; in other words, how many units of vitamin xyz do pigs require? Nevertheless, when organic forms of trace minerals are being used, their enhanced availability should be reflected in lowering overall feed specifications.

The availability of vitamins is quite different among certain sources and this, too, should be taken into account when these premixes are designed. Copper oxide, for example, is totally unavailable to pigs, yet it may be still found in low-cost vitamin and trace mineral premixes because it is the cheapest source of copper. Naturally, animals do not suffer easily from copper deficiency because copper provided by natural ingredients (maize, wheat, soybean meal, etc.) is usually sufficient and quite often above their requirements, but it may not be the same if non-conventional ingredients are used.All fiber is not equal

Fiber is undesirable in most formulas because it reduces energy density and nutrient digestibility. However, certain fibers with functional properties can be beneficial in improving animal gastrointestinal health. There has not been an agreement on which term best describes the fiber fraction in feed. Therefore, the term “crude fiber” continues to be the base on which pig ingredients are evaluated for most practical purposes.

Other more complex forms exist, but values for many pig ingredients are yet to be determined. Most importantly, fiber dietary specifications (minimum and maximum values) for pig formulas, other than those of “crude fiber” are very difficult to encounter in publicly available literature. All these imply that the term “crude fiber” is the best option for the present time, when all things practical are considered. Naturally, when it comes to functional fibers, there is a real paucity of credible information.Nutrient specifications

Table values such as those provided by government institutions are quite common in setting target values for the above nutrients. While these examples provide an excellent starting base, modifications are required to ensure specifications meet actual animal needs. Because of the generic form of such table values, not all cases can be covered. It is actual productive performance that should be used as a guideline in setting final formula dietary specifications. This ensures minimal feed cost and maximal animal performance.

This goal can be achieved through trial-and-error; via nutrient-challenge farm trials; or by employing the use of a growth model in the case of growing pigs. A cheaper feed does not have to be a feed of lower quality. To this end, using the correct tools (parameters and values) in formulating pig feeds, both guarantee animal performance and lower feed costs. Feed producers should be encouraged to ask their nutritional professionals about the latest and most advanced technology to be used when it comes to feed design and formulation. As feed accounts for at least 60 to 80 percent of total production cost, small changes in this area make for large savings.