Additive suppliers address the most common questions asked by nutritionists and feed producers and offer practical solutions.

In the grain and feed industries, the battle against mycotoxins, a series of toxic chemical byproducts produced by mold in feedstocks, and their effect on animal health and productivity is an evergreen concern, challenging poultry and livestock producers worldwide.

“Mycotoxins are among the most important feedborne stress factors to impact animal production,” says Clement Soulet, additives category lead for Cargill’s animal nutrition business. “Their adverse effects are numerous, and the financial loss associated with these invisible toxins is considerable.”

The true cost of mycotoxin contamination in animal protein production is unknown; however, it is imperative for nutritionists to mitigate their effects with feed additive solutions and for feed producers to properly monitor, handle and test their ingredients.

“Since mycotoxins are produced by molds as a natural defensive response to environmental factors – heat, oxygen or moisture – mycotoxin occurrence varies significantly by region, year and season,” says Rachel Tonda, associate product manager, Kemin Animal Nutrition and Health – North America.

In addition, variability in growing conditions, storage and handling also contribute to mycotoxin levels in individual lots of raw materials.

Here, we will examine the most common mycotoxin-related concerns posed by nutritionists, feed producers and growers, and offer best practices for combating these invisible foes in animal feed.

Identify true mycotoxin contamination levels

Unfortunately, there are no “safe” mycotoxin levels because these mycotoxins can have negative effects, either on their own or with other mycotoxins.

“Guidelines do exist for maximum desirable levels for a very limited number of mycotoxins, though these are not legal requirements, with the except of aflatoxin B1,” explains David Wilde, global innovation manager, Anpario plc. “Sadly, there is no global agreement on these levels, with some large variations between countries. These guideline limits should never be taken as a safe threshold since lower levels may not cause outward signs but, as research is now demonstrating, there is damage at the cellular level in the intestines, etc.”

The first step in a mycotoxin mitigation program is to identify and understand the true levels of mycotoxin contamination.

Mycotoxin analysis is commonly limited to identifying the “Big 6,” i.e., aflatoxin B1, deoxynivalenol (DON), zearalenone (ZEA), ochratoxin A (OTA), T-2 toxin and fumonisins (FUM), Wilde notes — but what about the other 500+ types of mycotoxins and their derivatives? With advancements in diagnostic testing and the frequency of analysis, growers and feed producers expect risk assessments to be based on the mycotoxin load but, in reality, any positive result means potential issues regardless of the level.

For example, with a better understanding of the negative effects of low levels of mycotoxin contamination, producers now regularly conduct FUM and DON analysis as part of their routine management protocol, says Maximillian Sim Kwang Hui, Technical Service Manager – APEC, Amlan International.

Arnau Vidal, technical manager – toxins and stress, Innovad, notes that recent large scale feed surveys have highlighted the consistent presence of a number of new and emerging mycotoxins, e.g., Enniatins, or those produced by Alternaria species, such as tenuazonic acid. More importantly, very new research has indicated the toxic potential of such mycotoxins to animals.

“Unfortunately, by ignoring those additional risks, we have a limited view of the overall picture,” Vidal says.

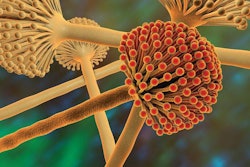

Mycotoxins are an invisible yet prevalent threat with effects on animal health, feed quality and protein production. (Kateryna_Kon | AdobeStock.com)

Mycotoxins are an invisible yet prevalent threat with effects on animal health, feed quality and protein production. (Kateryna_Kon | AdobeStock.com)Focus on mycotoxin exposure

While it is understood that high loads of mycotoxins will have clear and visible negative effects on animal health and performance, when it comes to lower contamination levels, the symptoms can be more difficult to detect and potentially result in mycotoxin damage being blamed on other factors.

“Mycotoxins are an invisible threat — invisible to our eyes and very hard to diagnose at the animal level,” notes Margaux Lecolinet, global marketing manager – mycotoxin management, Adisseo.

While current regulatory guidelines only factor in the effects of single toxin exposure, “this is rarely the case since molds produce multiple toxins under the same environmental conditions,” explains Tonda. “This means that although low-level toxin exposure and/or mycotoxin co-contamination may not cause overt signs of disease, they may be among the biggest factors in terms of impact on animal performance and lost profits.”

“We are missing the bigger picture by looking at mycotoxins only at the feed level,” Vidal says. “We are missing the obvious: the animal. It is necessary to combine feed and blood analysis if we want to measure the true impact of mycotoxins on animals.”

Based on the results of finished feed or raw material analysis, producers can obtain a risk estimation customized to their current situation from feed additive suppliers “to help them make the best decision regarding mycotoxin management at the feed mill — as well as to decide on the application of a mycotoxin deactivator — to ensure a cost-effective management of the mycotoxin risk,” Lecolinet explains.

Seek out real-time analysis

In the field, the absence of real-time information, occasional analysis, delayed results and lack of data consolidation and/or standardization are all factors contributing to ineffective decision making.

“For mycotoxin management, a non-targeted approach can result in a loss of time and money,” Soule says. “Adopting a more proactive strategy through better control procedures can generate substantial savings and, at the same time, improve feed safety.”

Mycotoxin testing and feed industry suppliers, such as Trouw Nutrition, Romer Labs, Neogen and Cargill, have been working to provide real mycotoxin risk assessment to combat these challenges, but they are not commonplace.

Evaluate feed additive solutions for mycotoxin mitigation

Despite the proven efficacy of many mycotoxin mitigants, which are comprised of various ingredients such as natural and modified clays, activated charcoal, yeast cell walls and phytogenic feed additives, Orffa’s central technical manager, Brecht Bruneel, warns that some mycotoxins are difficult to bind and that “a 100% solution may not be available.”

He suggests other “defense mechanisms” could be considered to mitigate the mycotoxin threat, such as intestinal integrity support and mold inhibition.

“In our opinion, a broad-spectrum additive solution is the way to go, as co-contamination of mycotoxins is most common and is well addressed by such type of product,” he says.

Dr. Raj Murugesan, technical officer at BIOMIN America, Inc., suggests the use of EFSA/FDA-approved microbial and enzymatic tools for mycotoxin detoxification.

Whether using enzyme-, yeast-, algae- or mineral-based product, Sim suggests controlling mycotoxins is dose-dependent: “The higher the challenge level, the higher the dose of the mycotoxin control product needs to be.”

Cost evaluation is difficult, says Julia Dvorska, Adisseo’s global scientific and technical manager – mycotoxin management, because the effects on the animal vary based on the species, age, sex, nutrition, environmental factors and, of course, the dose, type of mycotoxin and the duration of the exposure.

Meanwhile, the on-going assessment of the effects of mycotoxins on animal performance is a fundamental concern for feed producers, she says, in part for the safety and productivity of the animals, but also to ensure the producer’s willingness to adopt mycotoxin mitigation strategies.

“For example, mycotoxin deactivators are perceived as a cost by feed producers who carefully manage their return on investment,” Dvorska adds. “For these producers, if there are no measurable effects on the animal, there is not much reason to invest in mycotoxin management.”

Beyond mycotoxin exposure, other environmental or feed stressors may contribute to an animal’s diminishing health and productivity. (kowit1982 | AdobeStock.com)

Beyond mycotoxin exposure, other environmental or feed stressors may contribute to an animal’s diminishing health and productivity. (kowit1982 | AdobeStock.com)Closely review the trials, research

When researching or investing in mycotoxin mitigant products, Dvorska offers this advice to producers: Avoid judging mycotoxin product efficacy on in vitro studies because they do not correlate with in vivo results, e.g., with DON and other trichothecenes, FUM, OTA and many other mycotoxins.

“Most suppliers demonstrate the efficacy of their products via in vitro binding studies, which, in many cases, have nothing to do with the in vivo efficacy of the products,” she says. “Moreover, some of these products can have adverse effects, such as over activating the immune system, trapping key nutrients, increasing DON concentrations in distal parts of the intestine or even loading an animal with elevated levels of heavy metals.”

“An effective mycotoxin mitigation program is about science — not luck or probability,” Vidal says. “Mitigation technologies need to prove their systemic detoxification capacity, not only animal performance. Indirect evidence, extrapolated merely by animal performance data, is not adequate.”

Sim agrees: “It is very common to interpret the efficacy of a given mycotoxin control product based on in vitro analysis. However, to better correlate the effectiveness of a given product, we should always evaluate the result from animal studies.”

Adopt a holistic approach

Suppliers suggest complete, holistic mycotoxin management programs are the best, most cost-effective approach to mitigating the effects of mycotoxin contamination in feed and its impact on animal health and productivity.

For example, in post-AGP production, mycotoxins can predispose animals to diseases the antibiotics otherwise would have controlled, making them less obvious to producers, Murugesan notes, “Depending on the species, without antibiotics, gastrointestinal and reproductive challenges as well as behavioral issues, resulting in diseases and loss of productivity, have come to the forefront and mycotoxin contamination has been the underlying cause often times.”

“Hence, we suggest putting a comprehensive mycotoxin mitigation strategy in place to prevent and reduce the effects of mycotoxins and, in turn, eliminate the chances of diseases breaking out in the gut,” he says.

Vidal notes that it is necessary to take in account the animal’s other stressors in addition to its mycotoxin exposure.

“Animals in real production conditions are confronted with an overall stress, for example, climatic conditions, poor feed quality, feed changes and so on, always under the context of toxic contaminants,” Vidal says. “As such, comprehensive technologies with multiple modes of action that support the animal from several angles and boost its natural defenses are required.”

“The animal’s mycotoxin tolerance level changes according to the immune status of the animal. When the tolerance level of animals is reduced due to stress, even a low level of mycotoxins can pose a threat to the animal’s productivity and health, causing a profit loss for the producers,” Sim adds.

Prevention is better than a cure

According to Kemin’s Rachel Tonda, the mitigation of mycotoxin contamination in feedstuffs requires an integrated, preventative approach.

Focus on grain quality management: Managing grain temperature and moisture, reducing “hot spots” in storage bins and applying a mold inhibitor can help limit the chance for molds and mycotoxins to develop.

Test incoming grains for mycotoxins: Knowing which toxins are present in grains and their levels is key to identifying and addressing mycotoxin risks prior to feed manufacturing. Implementing a comprehensive mycotoxin testing program — which typically involves a feed supplier or mill sending samples to a certified laboratory — is critical to controlling not only mycotoxins but also the myriad of other illnesses and conditions they can cause.

Use feed additives designed to address mycotoxins: Working on a molecular level, these products target, denature/sequester and usher mycotoxins through the animal’s gastrointestinal tract to be excreted instead of being absorbed. Considering the high probability of mycotoxin co-contamination, mycotoxin adsorbents with broad-spectrum binding efficiency provide producers with the best ROI.