Pieter Steyn of Trouw Nutrition talks about how to keep feed ingredients safe from contaminants during shipping

PODCAST: How to ensure raw material quality during shipment (09:45)

Ann Reus: Hello and welcome to the Feed Strategy podcast. I’m your host, Ann Reus, staff reporter for Feed Strategy.

Joining me today is Pieter Steyn, global program manager for raw material quality at Trouw Nutrition. Pieter is responsible for providing technical support on raw material quality to Trouw Nutrition operating companies and customers around the world. His focus includes microbial risks associated with major grains such as corn and wheat, grain byproducts, oilseed protein meals and animal byproduct meals, as well as how to mitigate those risks in a solution-based offering.

So, Pieter, what kinds of contaminants affect feed ingredients the most and what ingredients are the most susceptible to contamination?

Steyn: OK, so, when we look at contaminants, we generally classify as microbes present, so, in the feed ingredients or compound feed, so, we mainly categorize this as bacteria or fungi, and then also yeasts. So, that is the main categories that we that we look at when we when we look at microbial risk in those said feed ingredients. And we also see a high prevalence in the high-protein feed ingredients like a soybean meal, rapeseed meal, and then also animal byproduct protein meal. So that that is the feed ingredients that are the most prevalent for bacterial Salmonella.

Reus: How can conditions during shipping and storage affect contamination levels?

Steyn: So also there, we look at a couple of factors that can really play a role in contaminating the feed ingredients. So, look at moisture content, relative humidity, oxygen temperature, and then also what we linked to moisture is also water activity, which is quite important because water activity is the amount of free water that’s available for the microorganisms to grow. So we really look at that as well when we analyze. But storage can really play a role in creating that perfect environment with all those factors for the bacteria to proliferate or for the molds to grow. So, it’s really important that we look at how we how we store the feed ingredients when we ship it or when we are in transport as well.

Reus: What are the economic repercussions of contaminated feed ingredients?

Steyn: So, when we look at losses – so there’s two different types of losses that we normally look at – so physical, and then also nutritional losses, and both has a huge economical impact. So, physical losses to explain a bit more, so that’s like the physical, when we need to discard the product or the feed ingredient basically because of spoilage. So, again, when we when we spoke about that perfect environment and that bacteria basically, normally the top layer, that we need to discard because of spoilage. And then also, when we look at nutritional losses, basically losing that essential nutrients or not all of it, but a part of it, basically degrading that nutritional value of the feed ingredients because the microbes present basically consume those essential nutrients and therefore the quality also significantly decreases and then also again at the end of the day, also has a huge economical impact when you physically measure those losses.

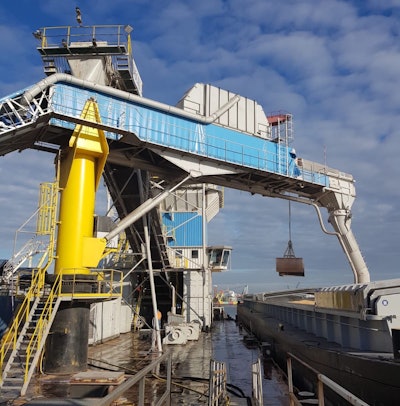

Reus: Now, before we move on, let me first tell listeners about the Rotterdam model, which is a feed safety approach from Europe’s largest port that is used to manage contamination risk in animal feed. To reduce the risk of contaminated ingredients entering the animal feed production process, a dry bulk terminal operator in Rotterdam collaborated with Trouw Nutrition on an approach that can also be deployed at feed production facilities. The terminal operator and Trouw Nutrition developed a three-part “product, service, knowledge” approach to treat feed materials in freight that test positive for Salmonella. Incorporating mechanical processes and systems, organic acids and precision dosing models, the Rotterdam model can treat 1,000 tons of freight per hour, which means a ship’s 20,000-ton cargo can be treated within a day. Here’s Pieter with more about how was it developed and how it protects feed ingredients against contaminants during shipping.

Steyn: So, I believe the partnership started about 10 years ago. There’s a lot of import of oilseed protein meals coming from South America. Also, with every shipment coming to the EU, they need to test for Salmonella because of the strict legislation in EU, that they prohibit any product that Salmonella contaminated to be sold in the market. So, Rotterdam saw a lot of the clients also having issues with Salmonella contamination. And also for us, being in the feed additive industry and also having a lot of expertise on some reduction strategies, I think that was a perfect fit. Also, we’re also looking at application as well, so they wanted a tailor-made solution. Because of the offloading speeds, when a ship comes in, obviously, keeping in mind that there’s obviously a lot of port duties that they need to pay, so there needs to be efficient offload and at high speeds. So we really looked at the expertise that we have, and that was a good fit with us with Rotterdam. So, basically, supplying almost a turnkey solution, so the whole solution where we incorporate services like lab services, as well as application, so basically dosing systems, and then as well as also the products and mainly organic acid based, that’s the products that we produce is organic acid based. So, specifically with Salmonella in mind, so formic acid so basically buffered acids that also has that long-lasting effect that can safeguard against recontamination as well. So yeah, the partnership still going strong. And yeah, we’re really happy with what we can collaborate on this with them.

Reus: What can different parts of the supply chain to do ensure the quality of feed ingredients during shipment and after they have arrived at their destination?

Steyn: I think it’s really a responsibility, I think, for the whole supply chain. Basically, providing safe feed for safe food, I think, looking at what we can do, I think it’s, we can look at, when we source feed ingredients, raw materials, we really look at the quality when it goes into storage, really making sure that we have the right storage capacity, and also the best practices that we can, in order to safeguard those feed ingredients against, like we said, bacteria, molds and also yeast, and also really look at to keep the nutritional losses at a minimum. So yeah, it’s just the responsibility to make sure that we safeguard against recontamination as well. And that that comes in, for example, before the shipment leaves, we make sure that if we store in that specific bunker or silo, a different feed ingredient that’s coming in that we really need to clean and make sure that we disinfect and keep feed hygiene at the highest priority on the list. I think it will just help in going forward when the feed ingredients come to the feed mill that they know they’ve got the best quality raw materials and clean raw materials, and then going forward to producing the feed for the animals to optimally perform as well. And to provide the safe food for us as the globe.

Reus: Can the Rotterdam model be used to protect against virus such as African swine fever that can live in feed during transport?

Steyn: So, we have not done validation on this per se. So, however, I know they there has been research done by the MDBA, and it’s not long ago. So, they basically saw that, for example, ASF is broadly stable across commonly imported feed ingredients. Basically, they don’t see it as a huge risk commonly. And they also basically saw that physical and chemical treatment may mitigate the risk of ASF introduction into the feed. So it’s almost like inconclusive, but for us, we have not done that validation yet from this perspective.

Reus: OK, well, thank you, Peter, for joining me today. It was nice talking with you.

Steyn: Yeah, thank you so much, Ann, thank you for having me. Yeah, it’s been great.

Reus: And thank you to the audience for listening. This is Ann Reus for Feed Strategy.