Animal protein production is a critical part of the food supply. Efficient production is driven by the animal’s access to complete, balanced diets. One of the main components of these complete rations is an adequate supply of amino acids found in protein-rich ingredients. Various kinds of soybean meal serve as an ideal ingredient due to their availability, price, and the quality and balance of their amino acids.

Canola serves as alternative to soybeans

As the demand for animal products increases, the availability of protein meals may become limited or cost-prohibitive. In addition, geopolitical crises and weakening economies in particular regions may also limit or prevent trade. This could be especially detrimental in parts of the world where soybeans do not grow or where soybeans/soybean meals must be imported. Therefore, it’s important to have local feed ingredient alternatives and nearby processing capacity.

Such alternatives will contribute to increased feed security. Similar and related to the concept of food security, feed security is the concept of having more of an immediate supply of the components necessary to produce livestock feed. In this regard and others, canola is an excellent choice.

Soybean meal vs. canola meal

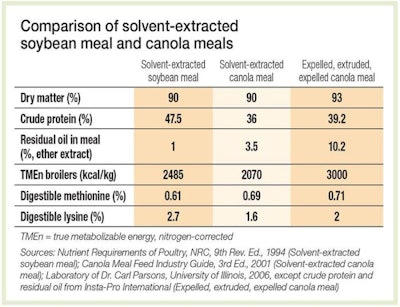

The oil-bearing crop grows in climates not known for soybean production. Like soybeans, canola seeds are processed into oil and protein-containing meal that is used in livestock feed. And, also like soybeans, how it is processed determines the quality of the ingredients (see Table 1).

Canola meals are good alternatives to soybean meal, especially when processed with expelling and extrusion.

First, soybean meal is a high-quality ingredient and will usually support more performance than either canola meals, especially in terms of lysine. Soybean meal provides more digestible lysine than the canola meals, and since lysine is often limiting in various livestock diets, more lysine to support growth and efficiency will increase animal production. Also, soybean meals naturally have less dietary fiber than canola meals, which also puts limits on canola use in diets because the fiber fraction can interfere with digestion.

However, canola meals provide somewhat more digestible methionine, which typically limits broiler performance. Finally, depending on how the canola is processed, canola meal has more or less metabolizable energy, e.g. solvent-extracted canola meal, which has less residual oil in the meal, is characterized as having less energy than expelled, extruded canola meal. An optimal energy level in a complete diet is necessary to maximize livestock performance.

The data in Table 1 also show the effect of the processing methods. The solvent-extraction method, which employs heating and solvents like hexane to maximize oil recovery from the meal, produces a lower feeding value in canola meal. Conversely, expelling and extrusion, which uses friction to rapidly rupture cells and heat the canola seeds for oil removal with mechanical presses (expellers), results in meal with higher digestible amino acids, more residual oil for energy and less water.

Processing considerations

Mechanical processing with expellers and extruders also benefits from the modular nature of the equipment (scalable depending on the size of the operation); the relative ease with which the equipment in the plant can be operated; and the fact that flammable solvents do not need to be stored and disposed of, and do not enter the food supply.

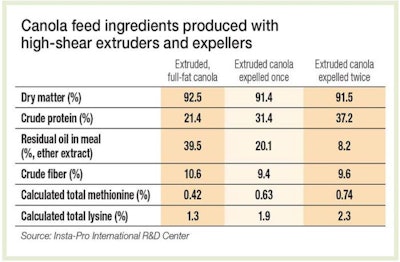

Canola ingredients that can be produced with an extrusion/expelling plant are varied and can be modified to reflect local and regional needs based on prices and availabilities of other ingredients, such as soy, as well as political and economic realities (see Table 2).

It is possible, but very rare, to feed canola after it has been extruded only – with all of the oil in the meal. Therefore, in temporary situations where there is no use for additional canola oil, low levels of extruded, full-fat canola meal could be included in livestock diets with other ingredients to support animal performance.

More common would be to extract some oil from canola for other purposes, such as cooking oil or biofuel production, and use the remaining residual oil in the canola meal as a source of energy. Experiments with either one or two passes through a mechanical oil press following extrusion, in a continuous production system, produced the results in Table 2.

Removing more of the oil results in a concentrating effect on crude protein and amino acids; therefore, more amino acids will be available in the same mass of canola meal to support performance and grow animal protein for food.

Also, reduced residual oil levels make it easier to formulate diets with more extruded, expelled canola meal. This is because high-oil diets are energy dense, and if not formulated properly by a nutritionist, will reduce feed intake and performance. However, with proper formulation, energy-dense ingredients can support more performance with a lower inclusion level of the ingredient.

Interestingly, while protein levels increase as more oil is extracted, detrimental crude fiber levels decline. This may reflect some effects of extrusion cooking on the fiber fraction of the canola seed.

The influence of regional needs

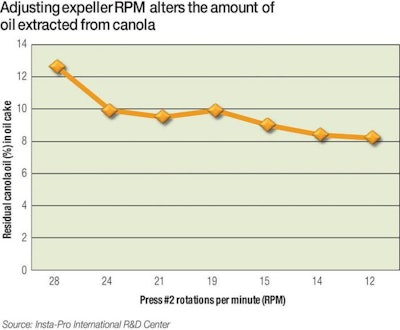

Besides using one or two oil extractions with an expeller, the speed of the screw inside the press (which works to force oil out of the meal after extrusion) can be altered to leave more or less oil in the meal. The effect of screw revolutions per minute (RPM) on oil residuals in the meal is shown in Figure 1.

Figure 1 clearly shows that reducing the RPM of the second oil press, after extrusion and pressing once in a continuous line, results in less residual oil in canola meal (or the cake that exits after the press, and is then ground into meal). Therefore, more oil was extracted from the meal. So, the RPM of the expeller is another variable that can be changed depending on regional needs.

Regionally grown and properly processed feed materials, such as those produced from canola, play important roles in supporting the livestock production sector, which is the major and reliable source of animal proteins in human diets. Having some local processing of canola with methods designed to make high-quality meal, such as extrusion and expelling, will make local feeds go further in supporting and enhancing animal performance.

Most importantly, it makes people less dependent on imports of raw materials and feed ingredients, which are in demand more and more around the world.