Corn is the major staple in diets for monogastric animals in many areas around the world. This is due to its widespread cultivation in arable lands and its ensuing competitive pricing. When high availability and low cost traits combined with the few, if any, anti-nutritional factors, and corn’s high nutritive value, it is easy to understand why this cereal has such prominent position in animal nutrition.

In fact, it is so widely used that many nutritionists and feed formulators take it for granted, neglecting to delve deeper in science to make the best out of its use. The following areas are very rarely considered, but they come up quite often, when corn is considered as a global commodity.

Prediction of energy

It can be safely assumed that on a dry-matter basis (DM), most corn samples can be expected to contain about 16.5 MJ/kg digestible energy. Although feed formulas can be adjusted for corn of different protein content (there are equations predicting amino acid concentrations based on crude protein levels), fluctuations in energy density are not taken into serious consideration. The opposite is true for wheat and barley, where the energy concentration is very variable, even more than in corn. Yet corn, despite its relatively standard composition, contains 75 percent starch, 4.5 percent fat and 2.5 percent fiber, all of which affect energy density. It is thus quite possible that even a small variation in these nutrients can bring about large changes in corn energy density.

To this effect, French researchers (Noblet’s group) undertook the task of developing a model to account for variation in chemical composition on corn’s energy density. In their studies, the digestible energy of 11 different corn samples was determined, with the differential method, in complete diets (35 percent corn) using 17-kg pigs. Gross energy of corn samples ranged from 18.4 to 19.7 MJ/kg DM, with an average of 19.07 MJ/kg DM. On average, energy digestibility was 88 percent of gross energy, giving about 16.78 MJ digestible energy per kg dry matter. The range of digestible energy, however, was from 15.5 to 17.5 MJ/kg.

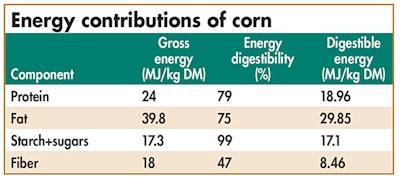

Presented in this table are the differences in energy contribution from the various chemical components that make up corn’s organic matter.

The following equation was then proposed as the one with the highest repeatability.

DE (MJ/kg DM) = 16.82 + 14.76 x (fat g/g) – 26.76 x (acid detergent fiber, g/g)

Crude fat and acid detergent fiber are two routine laboratory analyses that can be affected easily and relatively inexpensively, especially because corn is a major expense. Using this equation to adjust energy levels of incoming batches of corn can help reduce variability in animal growth performance.

Pelleting and high-oil corn

That pelleting improves efficiency of feed utilization (partly due to increased nutrient digestibility from thermal treatment and partly due to increased nutrient ingestion as feed volume is reduced) is well-established. The effects of pelleting on energy digestibility in corn, however, remain relatively less explored, and yet corn remains the main energy source.

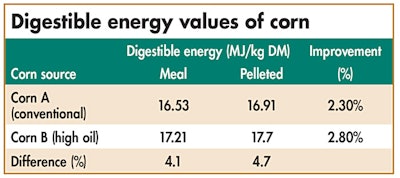

In a relatively recent study, two different samples of corn were used to determine the effects of pelleting on energy digestibility. Corn A (conventional) had 7.8 percent protein, 4.3 percent fat and 73.4 percent starch on a dry matter basis, whereas corn B (high-oil) had 9.5 percent protein, 8.2 percent fat (double!) and 67.3 percent starch. It is obvious that the extra oil has come at the expense of starch. Both samples were fed to 55-kg pigs as part of a complete diet. As expected, the high-oil corn B had more digestible energy (19.57 MJ/kg) than the conventional corn A (18.79 MJ/kg) because of the higher fat content. Pelleting improved fat (77 versus 61 percent in meal) and energy (91 versus 88 percent in meal) digestibility in both sources of corn. Thus, pelleting increased digestible energy in corn due to improved fat digestibility.

It is logical to expect, then, that high oil corn will benefit relatively more from pelleting than conventional varieties.

Presented in this table are the digestible energy values of meal versus pelleted corn.

White corn and carcass traits

White corn is grown in certain areas, and when this becomes available for animal feeding, it is interesting to consider its effect on pigmentation of carcass as white corn is devoid of the usual yellow-orange pigments. A study at Iowa State University evaluated the effects of white corn on fat color, firmness and composition. Pigs were fed diets from 28 to 130 kg body weight. The diets were based on white corn, yellow corn or barley (known to produce white and firm fat). As expected, pigs on a barley diet had carcass fat that was firmer, but not lighter in color, than fat from pigs fed either white or yellow corn (this was unexpected). It was also found that fat from barley-fed pigs had more saturated and monounsaturated fatty acids than fat from corn-fed pigs, which is in agreement with the fat composition of grains fed. No differences were observed between the two corn types.

In conclusion, white corn may be used interchangeably with yellow corn without any significant differences anticipated in fat quality. Barley yields fat that is most desirable by slaughterhouses and retailers, but not that desirable by health-conscious consumers.

Flow characteristics

It is well-known that roller-milled corn flows better than hammer-milled corn and that reduced particle size or added fat reduces flowability. Another U.S. research group recently pondered whether these flow characteristics of corn are affected by particle size distribution. They reconstructed corn samples (from previously sifted corn) to similar particle size standard deviation (about 1.2) but different mean particle size (300 to 1,400 microns). Fat was also added at 0, 4 and 8 percent. As expected, increasing fat reduced flowability, whereas roller-milled corn had better flowability than hammer-milled corn. Differences between roller-milled and hammer-milled corn were due to less particle size variation in the former type of processing. However, as mean particle size fell below 700 microns, other factors (such as particle shape) became important.

Read more: Practical grinding guidelines for pig feeds