These days, feed manufacturers are increasingly finding themselves defending their industry in the midst of heated discussions about sustainability and how best to feed the world. Although it is not always easy to find the right words to explain the complex feed industry to the lay person, here are five points to remember next time someone complains about environmental degradation caused by the livestock and feed manufacturing industries.

1) The feed industry actually fits nicely into nearly everyone’s definition of sustainable.

The United Nations defines sustainability as managing and conserving natural and human resources to meet the needs of today and the future. That’s exactly what feed manufacturers do – take products that are available, nutritious and wholesome, and use them to further food production in another way. Bakery feeds, wheat middlings, dried distillers grains and soybean meal would be considered waste products without the feed industry.

2) The feed industry is helping reduce greenhouse gas emissions.

Ruminants only contribute about 2 percent of the global greenhouse gases, but they draw a disproportionate amount of blame for methane and other gases in the atmosphere. Most of the methane is created as feed is digested in the rumen. Ruminants eat a plant-based food that is pre-digested by microorganisms in their rumen, then regurgitate the mass and chew it again. During this process – in which the rumen acts like a fermentation vat – methane is produced and expelled through the animal’s mouth. This process occurs whether the cow is eating grass on a pasture or concentrate in the barn. However, feed manufacturers are constantly identifying feed ingredients that encourage bacteria in the rumen to make less methane, while making more energy available for meat and milk production.

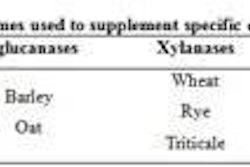

Methane released from manure is another target for greenhouse gas reductions. Some feed ingredients, such as bran, are not fully digested by swine. Many feed producers are adding digestibility-improving enzymes to feed, which increases the absorption of the feed components and enhances the value of the feed as a source of energy, protein and other ingredients.

Some analysts have estimated the contribution to global warming from pig production can be reduced by about 4 million metric tons of carbon dioxide each year by using an enzyme that is widely used in Europe. That’s equivalent to the annual emissions of nearly 1 million cars.

3) Feed production protects natural resources.

Feed manufacturers are constantly finding alternative feed ingredients to reduce the amount of nitrogen or phosphorus in manure and effluent. In fact, poultry producers in the Netherlands are currently required to use phytase in their production. Phytase is an enzyme that improves phosphorus digestibility and reduces phosphate in manure.

What’s more, not only does phytase reduce the amount of undigested phosphorus in the manure, but it also reduces the need to use inorganic phosphorus in the diet. Inorganic phosphorus sources are a finite material that is rapidly being depleted. Thus, by feeding an enzyme that allows pigs to better utilize phosphorus from cereals that are already part of the diet, depletion of inorganic rock phosphates can be slowed.

Feed producers are also actively looking to reduce nitrogen levels. Undigested protein in a poultry diet ends up in manure, which is rapidly converted to ammonia, nitrate and nitrous oxide. Ammonia emissions into the atmosphere cause water acidification or acid rain. Nitrate leaches into groundwater, putting drinking water sources at risk. Nitrous oxide – along with methane and carbon dioxide – contributes to global warming. Feed producers are both aware of this and working on a solution.

Research indicates that feeding protease, an enzyme, can increase amino acid digestibility by 3 percent to 8 percent, which allows producers to use less protein, primarily in the form of soybean meal. Less protein in the animal means less nitrogen in the manure and a lower risk of environmental harm from nitrous oxide escaping into the atmosphere or nitrogen leaching into water supplies.

Some studies have shown that feeding a protease can reduce nitrogen content of manure by up to 15 percent and ammonia emissions by up to 35 percent. This is a conservative estimate; other studies have put the savings much higher.

An estimated 15.9 million metric tons of broiler meat is produced each year in Europe and the limit for organic nitrogen application is 170 kg nitrogen per hectare. Feeding protease together with a low-protein diet would mean 80,000 fewer hectares of cropland would be needed to apply the manure – nearly the area of arable land in the Netherlands. Or, an extra 310 million 2- to 5-kilogram broiler chickens could be reared annually without the need for any extra land to dispose of the manure produced.

4) Feed manufacturers are reducing the amount of fish meal they use.

Forty years ago, poultry and swine diets used 90 percent of the fish meal produced. Now, those industries use less than one-third of that amount. Aquaculture feeds account for the rest, but even fish feeds are being reformulated to use less fish meal. Aquaculture producers in the U.S. have been working with plant breeders to develop low-phytate feed barleys to reduce the amount of fish meal used in the diet and the amount of phosphorus in fish effluent.

Five aqua-feed mills are participating in the Global Aquaculture Association’s Best Aquaculture Practices. Best Aquaculture Practices is a building-block approach to eco-labeling that includes one star if the processing plant is following sustainability protocol, two stars if the farm does also, three stars if the hatchery does and four stars if the feed mill does. Under the Best Aquaculture Practices guidelines, feed mills must source half of their fish meal from certified sources by 2015.

5) The world wants more protein.

World demand for quality protein from meat and milk products is increasing thanks to a growing population that has more disposable income. With the global population expected to reach 10 billion by 2050, many experts believe food production must increase by 40 percent to meet demand. And most agree that modern agricultural practices – which include fertilizing crops and commercially feeding livestock – are the most sustainable way to produce the food the world will need.

Related story:

Feeding 10 billion people: the challenge, www.WATTAgNet.com/21920.html