Production targets in the pork industry vary all over the world depending on market requirements and eating habits in different countries, but the main targets are high animal performance and health. With an increased target body weight, the feed conversion rate is higher due to the advanced age of the pigs when they reach their final weight. However, factors such as genetics, environment, feed, health, hygiene and housing influence performance independently of production levels.

In addition to diet composition and nutrient density in feed, two additional parameters influence the performance and health of pigs: feed form and particle size. Feed form is the physical structure of the final animal feed, such as mash, crumbles or pellets. Mash and pellets are mainly used in pig feed. The size of the single particles in the mash or pellets is defined by the feed particle size, expressed as the average particle size and particle size distribution.

Particle size has a major influence on pig performance and on the health status of the animals.

Feed form is of secondary importance

Feed form is of minor importance in pig feed compared with particle size. However, certain points must still be taken into consideration: pelleted feed has a higher nutrient density per unit of volume and can improve nutrient digestibility. Furthermore, feed wastage is reduced although feed intake is not clearly improved.

In addition, better product flowability, easier handling and transportation, the decreased risk of microbial contamination and reduced levels of dust are the main advantages of pelleted feed.

On the other hand, mash feed is less expensive to produce, and this leads to more cost-efficient pig production. In terms of feed intake, pigs can be fed mash without significant product losses as pigs do not differentiate between different particle sizes or the color of the raw material. Where mash is concerned, one critical point in terms of high feed intake could be the palatability of the feed, which is improved after pelleting.

The decision about feed form is very individual and depends on many factors. In general, additional pelleting costs should result in higher animal performance in order to achieve an economic balance.

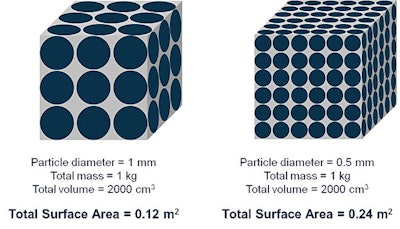

Increasing the surface area of the same volume by finer grinding of the raw material results in a larger total surface area. Therefore, enzymes have a larger area to attack the particles and to release nutrients. (Courtesy Bühler Group)

Particle size, a balance between performance and health

Modifying feed particle size significantly influences pig performance. The smaller the particles, the better the feed conversion rate. With finer grinding and the same volume of feed, a greater number of single particles are produced, which results in an increased total surface area. Therefore, a larger area is available for digestive enzymes to attack, resulting in accelerated nutrient release and absorption. Another consequence is increased metabolizable energy with decreasing particle size.

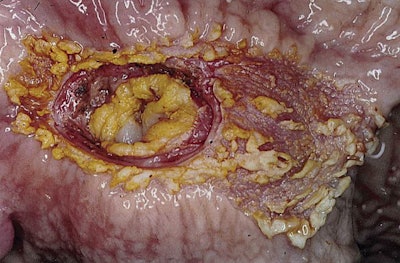

In addition to performance-enhancing aspects, health issues must also be considered as they limit the extent to which the particle size can be reduced in pig feed. One observation is the reduced development of the intestinal tract due to low stimulation by fine particles during digestion, which results in reduced gastric efficiency. Furthermore, numerous research studies demonstrate the link between the formation of gastric lesions and a reduced average particle size. This is because feed with fine particles produces more liquid stomach content.

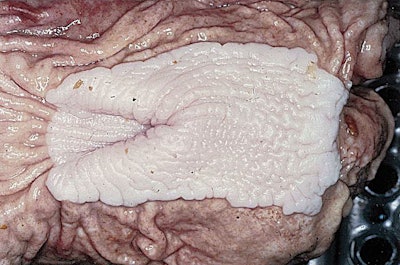

Comparison of a healthy digestive tract (top) with a severe ulcer in the pars oesophagea as a result of feeding a too-fine diet. (Courtesy Nielsen and Ingvartsen, 2000)

The stomach is divided into two areas with different pH values and epithelium. If the stomach contents become too liquid, this impedes maintenance of this segmentation. Therefore, the more acid content of the lower stomach can attack the more sensitive epithelium in the upper part and cause lesions.

Wide particle size distribution has a similar effect on the intestinal tract as a fine average particle size.

In summary, narrow particle size distribution and coarse particles decrease the incidence and severity of gastric lesions and ulcers. Therefore, it is necessary to find the right balance between animal performance improved by fine granulation and animal health improved by coarser granulation.

The influence of process parameters

During the grinding process, various factors, such as hammers, screens, tip speed, aspiration or roll gap, influence the size of the particle. In addition to the machine’s parameters, the type of raw material also has an impact on the final granulation and particularly on particle size distribution.

In pig feed production, a hammer mill or a combination of a hammer and a roller mill are commonly used. Even though the narrowest particle size distribution can be achieved, only using roller mills for pig feed makes no sense as the average particle size of pig feed ground on a roller mill is too coarse.

Furthermore, sufficient grinding of fibrous components, such as barley, is not possible. A further reduction of average feed particle size occurs during pelleting depending on the machinery used, the process and the type of raw material.

Guideline values for particle size in pig feed

A healthy digestive tract is important to achieve high performance throughout the entire growth period. Therefore, especially for older animals, it is essential to adapt the feed particle size not only with a view to achieving maximum performance, but also with the aim of ensuring a sustainable health status for the animals.

The recommendation for the particle size for growing pigs is 400-700 microns, taking growth performance, stomach morphology and nutrient digestibility into account. For piglets, a finer particle size in the range of 200-400 microns is appropriate on account of their digestive system, which is still underdeveloped.

In pig feed, particle size must be adapted to the physiology, digestive system and age of the animals as well as to the farm’s production targets and individual requirements.

Average particle size and particle size distribution are influenced by the raw material as well as by the mill type, and the grinding and pelleting process parameters. For this reason, it is important to focus on feed processing aspects as well as on nutrients and diet composition.

Particle size is the ideal tool for finding a compromise between performance, health and optimized feed efficiency.

Editor’s note: This is the first installment of a five-part series, “All about particle size: the influence of feed particle size on animal performance,” contributed by the Bühler Group. It aims to explain the importance of particle size in pig and broiler feed, and explore the possibilities for modifying and controlling particle size during feed processing.