Take into account the additional grinding effects of the pelleting process during feed manufacturing

Grinding has the most obvious impact on particle size during the production of animal feed; however, a further reduction in particle size can be observed during pelleting, but this additional grinding effect is often ignored. Therefore, a study has been conducted to evaluate the various factors that influence the reduction of particle size during the compacting process.

Determination of particle size in feed pellets

Determining the size of the particles in feed pellets is challenging due to forces that bond the particles formed by pelleting. Therefore, it is difficult to compare the initial granulation with the actual particle size in the pellet.

Granulations can be compared by wet sieving. The pellets and the initial product are dissolved in a solvent and sieved under wet conditions. To achieve a comparable result, the sample must be prepared in the same way both for the initial product and for the pellets. The sieving fractions are dried and weighed at a later stage for evaluation.

Although this method does not detect soluble parts in compound feed, it still provides the best indication about the grinding effect during pelleting.

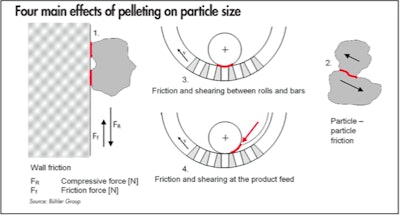

Figure 1: Friction and shearing forces affecting particle size during pelleting: 1. Friction forces between particles and the die-hole-wall. 2. Friction forces between particles. 3. Friction forces between rolls and bars. 4. Friction and shearing at the product feed. (Courtesy Bühler Group)

Figure 1: Friction and shearing forces affecting particle size during pelleting: 1. Friction forces between particles and the die-hole-wall. 2. Friction forces between particles. 3. Friction forces between rolls and bars. 4. Friction and shearing at the product feed. (Courtesy Bühler Group)Forces exerted on particles during pelleting

Particles are ground during pelleting by means of compressive friction and shearing forces. These are the four main effects of the forces acting on the particles:

- Friction occurs between the die-hole-wall and the particle itself as well as between different particles. Parts of the particles can break off and abrasion occurs on the surface of the particles.

- The product is compacted in the die holes and particularly brittle particles break under the compressive forces.

- Depending on the size of the roll gap, the particles between the press roll and the die bars are exposed to friction and shearing forces.

- The particles are compacted at the angle of nip, where the product is fed into the roll gap. Particles break under compressive and friction forces.

Influencing factors during pelleting and their effect on particle size

Granulation of the product is influenced by several factors with regards to the raw material, the machinery and the process.

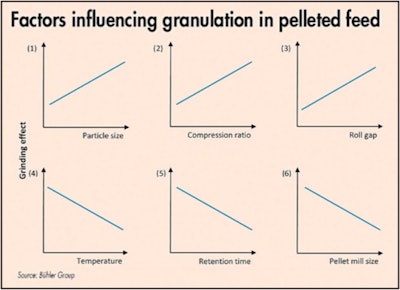

The raw material has a special significance in feed processing due to the wide variation of the composition and regional differences. Figure 2 shows, in general, the main effects of the different factors influencing granulation with a focus on machine- and process-related parameters.

Figure 2: Influences of increasing particle size, compression ratio, roll gap, temperature, retention time and pellet mill size on the granulation in pellets: First line: the grinding effect increases with (1) increasing particle size, (2) increasing compression ratio, (3) increasing roll gap. Second line: the grinding effect decreases with (4) increasing temperature, (5) increasing retention time and (6) increasing pellet mill size. (Courtesy Bühler Group)

Figure 2: Influences of increasing particle size, compression ratio, roll gap, temperature, retention time and pellet mill size on the granulation in pellets: First line: the grinding effect increases with (1) increasing particle size, (2) increasing compression ratio, (3) increasing roll gap. Second line: the grinding effect decreases with (4) increasing temperature, (5) increasing retention time and (6) increasing pellet mill size. (Courtesy Bühler Group)Graphs 1 to 3 in figure 2 show that the grinding effect increases with increasing particle size, compression ratio and roll gap. In contrast, the increase in temperature, retention time and pellet mill size reduce the grinding effect (figure 2, graphs 4 to 6).

- Initial particle size

The initial particle size has a significant influence on the final granulation after compacting. In general, the grinding effect increases with increasing average particle size (d50). Larger particles are more affected by shearing and compression when they are forced into a die hole with a constant diameter.

- Compression ratio

The compression ratio is the ratio of the die hole diameter and the press channel length of the die hole. With an increasing compression ratio, the compressive forces and friction forces inside the die hole increase, and more particles (especially brittle ones) break under these forces. Therefore, the grinding effect increases with a higher compression ratio.

- Roll gap

The gap between the die and the rolls works like an elongation of the active die length. Therefore, the increased roll gap acts like a higher compression ratio. The particles are pre-compacted by repeated overrunning by the rollers before the feed is forced into the die holes. These compressive forces increase with larger gaps, and the grinding effect is intensified.

- Temperature

The conditioning temperature is regulated by the addition of steam. The added steam condensates when it comes into contact with the colder surface of the product. Therefore, temperature and moisture are linked: with increasing temperature, the moisture content also increases, which is why more moisture is available, making the particles softer and more elastic. Furthermore, the moisture acts like a lubricant in the die hole, reducing friction forces and abrasion. Altogether, the grinding effect can be reduced by an increase in temperature mainly caused by the related increase in moisture.

- Retention time

After conditioning, the particles are kept at a constant temperature and moisture level during retentioning. The moisture on the surface of the particles is absorbed during the retention time. With longer retentioning, more moisture can be absorbed, and the particles can be heated more thoroughly. Forces acting on these soaked particles lead to less fractures and more elastic deformation, resulting in a reduced grinding effect with increasing retention time.

- Pellet mill size

During the study, it was observed that the grinding effect during pelleting decreases as the size of the equipment increases. With a larger die diameter, the circumferential die speed usually decreases. Thus, the rolls run over the particles less often and the motion of the feed mash inside the die hole is therefore higher per roll overrun. Furthermore, the angle of nip changes due to the increase in the die- and roll-diameter, which is why intake and pre-compaction are gentler.

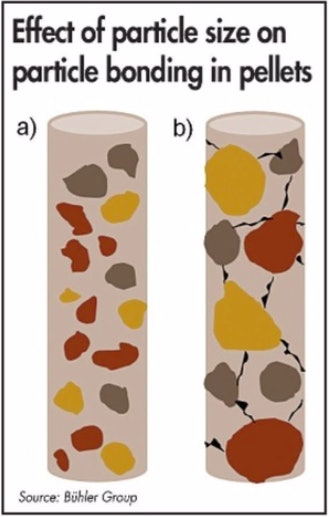

Figure 3: Fine particles act like glue, achieving high pellet quality (a), while coarse particles can be a source of fracture in the pellet and lead to low pellet quality (b). (Courtesy Bühler Group)

Figure 3: Fine particles act like glue, achieving high pellet quality (a), while coarse particles can be a source of fracture in the pellet and lead to low pellet quality (b). (Courtesy Bühler Group)Influence of particle size on pelleting

The influence of pelleting on particle size has been discussed; however, the initial particle size also has a significant influence on the pelleting process and especially on pellet quality.

During conditioning and compaction, liquid and solid bridges on the particle surface are formed. Coarse particles are a source of pellet fracture because they have a smaller surface area and are less solid, which means that liquid bridges form on their surface. The risk of transverse cracks increases with increasing particle size in relation to the die diameter.

In contrast, fine particles act like glue and form a better and tighter framework due to the larger overall surface area where single particles stick to each other due to cohesive forces. Therefore, pellet quality improves with decreasing particle size.

The importance of particle size during pelleting for animal nutrition

As particles size should preferably be fine to achieve high pellet quality, a conflict occurs regarding nutritional requirements, especially where poultry feed is concerned. For chickens, coarse particles are required to achieve good animal performance. But these coarse particles have fewer binding properties and the pellets break easier, creating fines and therefore increasing feed loss.

The grinding effect during pelleting is generally not taken into account. Particle size is only determined after grinding, whereas the actual particle size in the pellets is smaller than the required size.

By combining knowledge about the physiological requirements of animals and the effects of processing using process control, particle size adaptation can be an ideal tool for optimizing animal performance and health, as well as improving feed production.

Editor’s note: This is the final installment of a five-part series, “All about particle size: the influence of feed particle size on animal performance,” contributed by the Bühler Group. It aims to explain the importance of particle size in pig and broiler feed and explore the possibilities for modifying and controlling particle size during feed processing.