The increasing availability of amino acids allows feed formulators to efficiently move from a formulation based on dietary crude protein to one based on essential amino acids. A high degree of amino acid precision can result in a drastic decrease of dietary crude protein (CP) levels while maintaining the performances of pigs. Nowadays, it is possible to formulate diets without minimum constraint on the CP level in which seven amino acids are co-limiting – lysine being the first of them and threonine the second.

This is good news for feed manufacturers. In fact, looking for proteins is the core business of feed formulators dealing with nitrogen nutrition. Unstable raw material prices drive buyers mad. Apart from soy and other plants rich in protein, every piece of amino acid content must be used, e.g. alfalfa, gluten, cereal byproducts, algae, etc.

At the same time, environmental regulations are binding farming extension (or survival) to efficient effluents and waste farming management. In the EU, for example, extension is linked to the ability of the farm to get rid of its nitrogen waste. Nitrogen reduction is a key point for farmers.

Moving to the ideal protein concept

It is now well known that the total amino acid supplied from feedstuffs cannot be entirely absorbed by the animal’s digestive tract. Formulators use digestible amino acid rather than total ones to avoid paying too much for the raw materials being wasted by animals. CP-based formulation leads to excessive waste when it is inaccurately included in a formulation because of “limiting amino acid.”

In the ideal protein concept, researchers recommend the precise amount of digestible amino acids. Apart from precision, this concept is also very important in the hierarchy of amino acids with the notion of “limiting amino acid.” If the animal does not receive an adequate amount of the limiting amino acid, it will not be able to use the amount of other amino acids even if they are present at a sufficient level. It is like if the animal was a kind of barrel – the requirement of limiting amino acid would be the staves of different levels, with the first limiting amino acid being the smallest stave and giving the real “barrel’s content,” as explained by Leibig’s law.

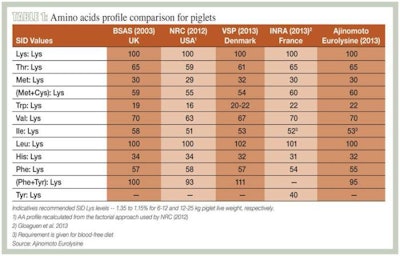

The requirements in ideal protein are expressed relative to lysine, the first limiting amino acid for growing pigs.

Research goes even further. In October 2013, three French researchers from Inra published an update on amino acid requirement for piglets*. They show that excess in some amino acids can reduce growth due to competition for catabolism and transport.

An excess leucine supply aggravates, for example, the effect of a valine deficiency. Researchers plead for a better adequacy to be sought between the supply and requirements. The same team succeeded in producing a pig ration without soymeal. They tested to what extent the CP content of piglet diets can be reduced by substituting soybean meal with wheat, barley, corn and free amino acids without affecting performances. The trial shows there might be a minimum of nitrogen between 13 and 14 percent CP; however, it confirms that tremendous dietary protein reduction is achievable.

Research establishes requirement, industry produces free amino acid

Dietary management aims at improving the efficiency of the ration and decreasing the amount of waste. The best option is to bring the exact amount of amino acid needed by each animal at each stage or each situation, as it may influence the requirement. Once research determined the precise requirement of each essential amino acid in pig nutrition, the industry took its turn: lysine and methionine, then threonine, tryptophane and, recently, valine are now produced in industrial volumes.

With more than 2 million metric tons in 2013, lysine consumption is still going up over the world. The same trend is shown with threonine (400,000 metric tons) and tryptophan (15,000 metric tons) explained Olivier Hartz, vice president sales and commercial operation of Ajinomoto Eurolysine SAS, who presented at “Vigie Matières premières debate,” annual congress for feed manufacturers in Paris.

Between 2007 and 2013, European meal use decrease by approximately 5 percent. Soybean meal lost 7.6 million metric tons, which had been only partly compensated by rapeseed meal and sunflower meal. This “deficit” has been compensated by two trends: the increasing incorporation of cereals (+5 percent) and free amino acid use (+65 percent); and decreasing CP (-30 percent). The movement, started with environmental considerations in mind, is now well under way because of protein scarcity.

European feed formulators move to more concentrated formulas

Hartz, who presented results of Ajinomoto Eurolysine SAS’ survey, explained that formulators have already taken the opportunity to reduce CP content in European pig rations, going for a more concentrated formula through protein reduction and lysine incorporation.

For example, between 2008 and 2013, the average lysine/CP percentage in piglet feeds went from 6.5 percent to 6.73 percent. Formulator’s responsiveness to those new practices varies between EU countries. For example, Finland was already very high in 2008 (6.89 percent); while Germany and Italy reach 7.01 percent in 2013. The Netherlands went from 6.34 percent in 2008 to 6.51 percent in 2013, and France went from 6.47 to 6.8 percent.

Regarding the formulation for growing pigs, which has more impact as volume is much more important than in piglet feeds, the move began earlier: Italy didn’t move much between 2011 and 2012 (5.88 percent); feed producers in Belgium and the Netherlands were more responsive (6.3 and 6.48 percent, respectively). The French progressed, but more slowly (5.95 percent in 2011, 6.12 percent in 2012). Spanish formulators stay more stable (6.32 percent in 2011, 6.41 percent in 2012).

The decision to formulate with free amino acids could drive substantial savings, Hartz says, “going from 16 percent to 14.5 percent of CP in growing pig ration with tryptophan aid — and without minimum protein constraint — could drive to a saving of €3 (US$4) to €15 (US$20.5)/metric tons of pig feed depending on raw material costs.”

For example, depending on the maize incorporation rate (38 or 65 percent), free amino acids use saved feed manufacturers €14 (US$19) to €15 (US$20.5)/metric ton, presenting an opportunity that is difficult to pass by.

* M. Gloaguen, N. Le Floc’h, J. Van Milgen, “Update on amino acid requirement for piglets fed with low crude protein diets, Inra Productions Animales.