Drought conditions in regions throughout North America have placed a great deal of pressure on cattle ranchers and dairy farmers, particularly in regard to the cost and availability of hay this winter. In many areas, ranchers are faced with a difficult choice: either stretch existing supplies of hay or purchase additional hay at prices significantly higher than a year ago. Dairy quality hay in Idaho, for example, is selling for around $240 per ton, up nearly $100 from a year ago.

The U.S. Department of Agriculture’s latest biannual look at U.S. hay stocks shows the lowest December 1 on-farm hay stocks in 23 years. Hay stocks on all U.S. farms totaled 90.7 million tons as of December 1, down 11% from a year ago. U.S. growers harvested 19.2 million acres of alfalfa and alfalfa mixes in 2011, the smallest harvested acreage total since 1949.

New and improved hay feeder and bunk designs can help maximize on-hand stocks of hay to last through the winter. However, it appears that the best solution for maximizing hay stocks may be simply good management.

Comparing designs

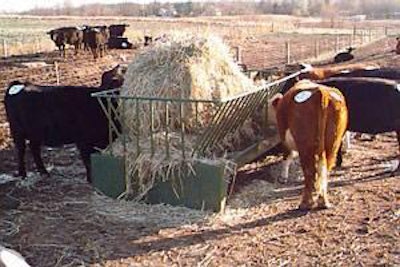

Michigan State University Extension Beef Specialist Daniel Buskirk has noticed over the years that some producers seem to be able to stretch their hay supplies longer than other producers. He set up a feeding trial to look at four different hay feeder designs to determine which design wasted the least hay.

Buskirk compared a ring feeder, cone feeder, cradle feeder and trailer feeder in the study. In addition to weighing the amount of hay fed and the amount wasted, the feeders were also videotaped, and the resulting footage was analyzed in terms of cow behavior.

Feeder designs with the greatest recorded hay waste were also the ones where cattle displayed the most antagonistic behavior. These feeders all had one thing in common: they had straight edges. “The longer, more linear the feeder is, the more cattle jockey for position,” Buskirk said.

Since cattle are hierarchal creatures, designs that have straight edges, such as the cradle feeder, allow a more dominant cow to push a less dominant cow out of the feeder. The displaced cow in turn pushes the next cow over and so on until the last cow is pushed off the feeder. Each time an animal is displaced, it takes a mouthful of hay with it that usually gets dropped on the ground.

Since cattle graze with their heads down, they don’t like to eat with their heads elevated. Although the trailer feeder has obvious advantages for a cattle producer because it can be easily moved from pasture to pasture, trailer feeders often force cattle to reach up for the hay. Video footage showed that cows often would reach in for a bite of hay and then back out to eat the hay in the preferred, head lowered position, often dropping hay in the process.

Circular feeders that provided regular entrances for the cows wasted the least hay, but Buskirk cautions that part of that success came from putting a 5-foot diameter round bale in a 7-foot 6-inch diameter feeder. Giving cows enough room to put their head into the feeder when they start to feed on a new bale is the key to reducing waste. If the bale is roughly the same size as the feeder, cows can’t reach all the way into the feeder and will drop some hay outside where it can be trampled on. Using a hay saver ring on a circular feeder will also reduce hay wastage.

A “hybrid” style created by GoBob Pipe and Steel features vertical bars that allow for cows to reach their heads in to eat, and a horizontal top bar prevents them from dragging the hay back out. The feeder can hold both round and square hay bales and the manufacturer claims the design reduces waste by one-third.

Feed bunks

Another option for feeding cattle is feed bunks. Like the hay feeder, there are important factors to consider when selecting a bunk and its construction.

Cattle can easily push plastic feed bunks around the yard and can punch a hole through the plastic if they step into the trough. Concrete bunks require regular maintenance. Since concrete is porous, it must be sealed on a periodic basis or it will spall or chip. Concrete bunks are also heavy and cumbersome to move.

Another feed bunk option is one constructed of metal. These offer enough weight to prevent animals from moving them around, but they are light enough to be moved by producers. Another “hybrid” approach – concrete reinforced with steel – is another option.

Management still key

Although design of a hay feeder or feed bunk is important, Buskirk says management is still the most important tool for reducing waste. Cattle that are fed only what they will eat within a day, waste less hay than those given enough hay for three or four days.

“My recommendation is a well made ring feeder that’s a got a real high hay saver ring with an adequate diameter so the cows have to put their head inside the feeder when you first put a new bale in,” Buskirk said. “That will give producers a pretty good balance between dollars invested and hay wasted.”