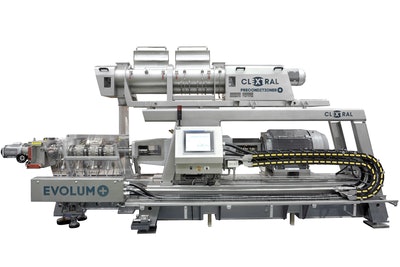

Food and feed processors can achieve increased capacity and highest product quality with the addition of the Clextral Preconditioner+ to optimize their extrusion process. Designed for operation with both single screw and twin screw extruders, Preconditioner+ units are engineered with dual sets of counter-rotating, intermeshing and adjustable paddles that ensure perfect mixing, plus liquid injection ports which can be precisely positioned to maximize liquid ingredient absorption.

These features generate homogeneous, pre-treated material for top quality products at higher extruder throughputs with reduced SME (specific mechanical energy) and residence time. With lower torque and shear requirements, extruder screws and barrel will also experience less wear.