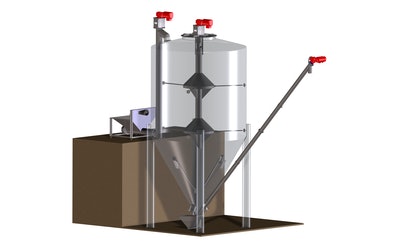

Van Beek has developed the vertical silo mixer for mixing and homogenising free flowing, dry substances of different sizes and with different bulk densities. The silo mixer creates mass flows within the mixing silo, its operation can be compared to that of a chocolate fountain.

The silo acts as a mixing vessel containing a vertical central tube fitted with a mixing screw. The mixing screw transports the product to be mixed from the bottom to the top and carries it upwards, after which an (optional) distribution plate spreads the product. By gravity and because the mixing screw creates space at the bottom the product next to the mixing screw falls back down on its own.

Using a silo as a mixing vessel gives a large mixing capacity and no residual product is left behind from a previous batch. The maximum diameter of the silo is 3.5 metres with a maximum capacity of 60-70 m3/hour. Suitable materials for homogenising in a silo are for example dry cattle feed, recycled plastic, grinding stock, etc.