Discover how enzyme-treated soy protein like Hamlet Protein’s HP 100 offers a sustainable, cost-effective alternative to traditional milk proteins in CMRs.

Brand insights from Hamlet Protein

Is it necessary for calf milk replacer (CMR) to contain exclusively milk-derived protein to be regarded as a high-quality product? Not necessarily. New research shows that alternative protein sources, such as Hamlet Protein’s HP 100, can maintain animal performance while reducing costs and controlling environmental impact.

Hamlet Protein’s HP 100, an enzyme-treated soy protein, mimics the amino acid profile of milk. Its patented process neutralizes anti-nutritional factors, ensuring high digestibility and proven efficacy in pre-ruminant calves.

For several decades, milk proteins (caseins or whey products) have been considered the cornerstone of CMRs for young ruminants. They are the recommended ingredient for pre-ruminant calves due to their amino acid profile and digestibility.

However, average dairy protein prices have increased steadily over the past ten years, driven by a combination of the volatility of the global market for feed ingredients and additives, the feed versus food competition, as well as the environmental and regulatory growing constraints on dairy production. It is time to reconsider the protein source in CMR formulation – here are five reasons why.

Growth performance on par with dairy proteins

While milk proteins have long been the benchmark for calf growth, recent studies have begun to challenge this assumption by evaluating alternative sources like HP 100 under real farm conditions. Trials conducted in Europe and the United States show that calves fed with a CMR containing a significant percentage of HP 100 in the formulation demonstrate growth performance comparable to those fed solely with dairy proteins.

The work of the University of Illinois in 2021 confirmed these results: the substitution of 50% of whey protein concentrate by HP 100 in a CMR resulted in equivalent performance in terms of weight gain and protein efficiency.

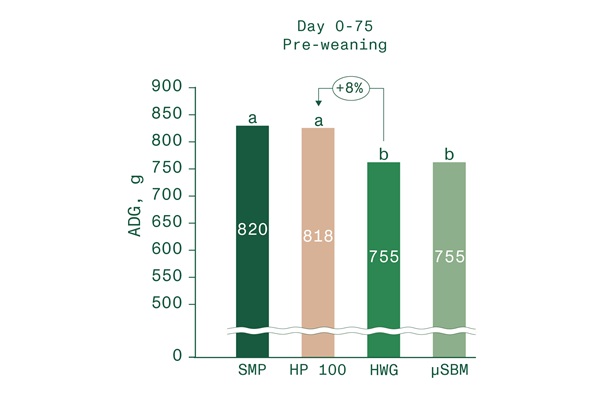

A recent university trial conducted in Poland in 2024 (Figure 1) demonstrated that calves fed a calf milk replacer (CMR) containing HP 100, accounting for 30% of their protein intake, exhibited average daily gains comparable to those in the control group receiving skimmed milk powder.

Watch a video explaining the 2024 trial results.

Furthermore, these gains were superior to those observed in calves supplemented with conventional vegetable proteins such as micronized soybean meal and hydrolyzed wheat gluten. Formulating with HP 100 offers the opportunity to reduce dependence on milk without affecting growth or consistency of performance.

Figure 1: Average daily gain (ADG, g) on day 0 to 75 after birth of calves fed a calf milk replacer (CMR) based on skimmed milk powder (SMP), or CMRs where 30% of dairy protein was replaced by enzyme-treated soybean meal (HP 100), hydrolyzed wheat gluten (HWG), or micronized soybean meal (µSBM). a,b indicates significant difference lower than P<0.05

2. Equivalent digestibility to dairy proteins

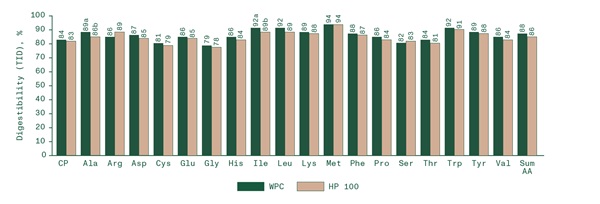

Traditionally, the primary challenge associated with incorporating soybeans into CMRs has been their digestibility. The very young ruminant, close to monogastric status, has a digestive system highly sensitive to complex proteins. Hamlet Protein's proprietary enzyme treatment overcomes this barrier: HP 100 has an ileal digestibility of proteins and amino acids equivalent to that of whey proteins, the market reference for assimilation by young animals (Figure 2).

This performance is based on the presence of a high proportion of small peptides (<500 Da) due to the enzymatic hydrolysis process. These peptides are quickly absorbed, reducing nitrogen loss and ensuring essential amino acids reach key organs like the rumen, intestines and lungs.

Another noteworthy point is the capacity of HP 100 to provide microbial protein when part of the liquid feed escapes the esophageal gutter, promoting early rumen fermentation with vegetable material.

Figure 2 True ileal digestibility (TID, %) of crude protein and amino acids in whey protein concentrate (WPC) and HP 100 when fed in CMR. a,b indicates significant difference (p<0.05).

3. Better gut health

Gut health is a key factor in the success of dairy calf pre weaning feeding program. Neonatal diarrhea remains one of the leading causes of economic losses and mortality in young calves. HP 100 provides a concrete answer: the enzymatic process drastically reduces soybean natural anti-nutritional factors, such as trypsin inhibitors, galacto-oligosaccharides and β-conglycinin, responsible for intestinal inflammation and undesirable fermentation in the hind gut.

The experimental results are clear: in the Illinois University trial, calves fed HP 100 had an average fecal score of 1.7 compared to 2.8 for the WPC group (p<0.01), a sign of a significant reduction in digestive disorders. These positive effects translate into better nutrient absorption and reduced sanitary costs related to antidiarrheal treatments.

4. Sustainability meets cost efficiency

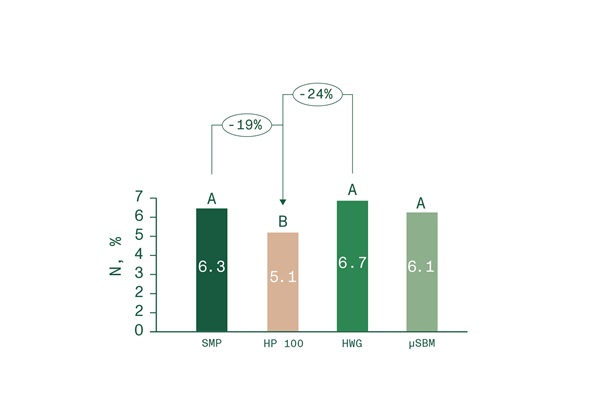

Beyond the technical aspect, the HP 100 meets a double imperative to do better with less: in this case, to reduce the environmental footprint while controlling costs. On the environmental front, HP 100 has recently been able to demonstrate (Figure 3) that it helps reduce fecal nitrogen emissions. Better digestibility coupled with rapid protein assimilation results in lower nitrogen excretion and therefore a lower impact of livestock manure on the livestock environment.

In economic terms, dairy proteins often account for 60-80% of the total cost of a CMR. By substituting a portion of these proteins with HP 100, formulators can contain the material cost of CMR without compromising performance. What's more, plant-based raw materials directly derived from legumes make it possible to avoid the use of nitrogen fertilizers which is rarely the case when you produce protein out of milk.

Figure 3: Nitrogen concentration (N, % of DM) in week 1, 5, and 10 of calves fed a calf milk replacer (CMR) based on skimmed milk powder (SMP), a CMR where part of SMP has been replaced by enzyme-treated soybean meal (HP 100), by hydrolyzed wheat gluten (HWG), or by micronized soybean meal (μSBM). Different letters indicate significant difference (A,B; P<0.01).

5. An easier weaning transition

HP 100 also plays a critical role in the calf's dietary transition to solid feed. Trials like the recent one in Poland show that calves fed a CMR containing HP 100 consume more dry feed in the pre-weaning period. Calf having HP 100 were consuming 14% more dry feed than those fed with SMP based CMR and 27% and 299% respectively than HWG and µSBM based CMRs in the 30-75 days period. This early stimulation of solid feed ingestion behavior promotes the development of rumen and its microbial flora as well as rumination and salivary secretion. The transition to weaning is eased: calves, through better rumen preparation, maintain regular growth and a robust appetite for solid feed.

A new generation of CMRs

HP 100 redefines the standards of modern CMRs. By linking digestibility, digestive safety, performance and sustainability, it provides a complete response to the current challenges of formulators and farm users.

Trials conducted on several continents confirm that it is possible to perform as well as 100% dairy CMRs while reducing costs and environmental impact. Rethinking the formulation of milk replacers is no longer an option: it is a necessary evolution towards more efficient and sustainable nutrition. HP 100 is thus a pivotal ingredient in the new generation of CMR formulas, combining profitability, animal welfare and environmental responsibility.

By Nicolas Anglade, Category Manager Ruminants, Hamlet Protein