Traditional US broiler feed formulations

Diet formulas include corn, soybean meal, poultry meal & antibiotics

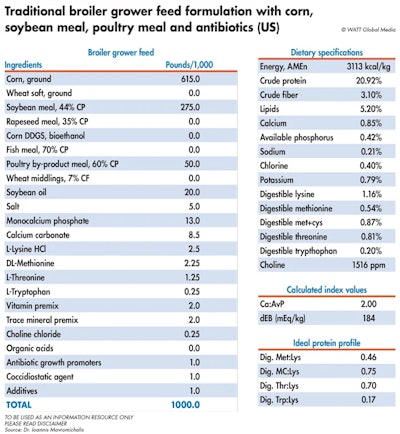

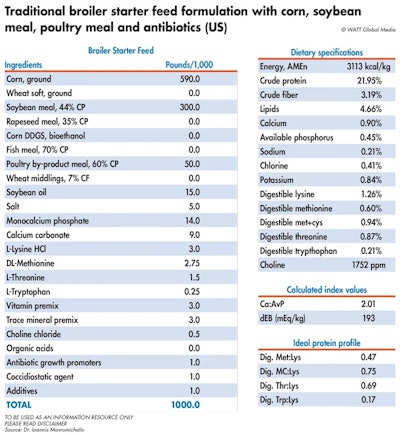

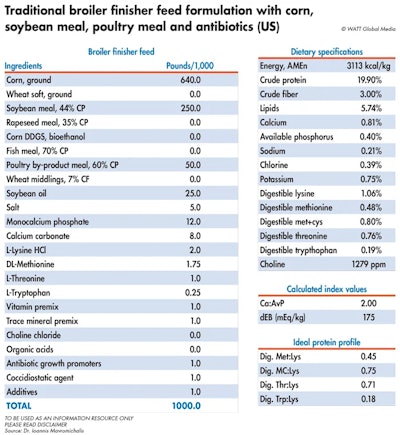

The first set of broiler formulas (BR01) in the Animal Feed Formulations Library describes what the majority of the world, and especially the United States and many Latin American countries used before the advent of the antibiotic-free era.

Notes on feed ingredients

These formulas are based on corn as the main energy source, supplemented by soybean oil. Of course, other cereals such as sorghum and wheat are available, and a plethora of other oils and fats are used. The end result remains the same, but it requires some further refinement and more attention to ingredient quality when we depart from classic ingredients. As such, corn and soybean oil remain the standard ingredients used to describe typical U.S. broiler formulas.

The same applies to soybean meal, which here is of the 44% crude protein variety — although many nutritionists prefer the 48% crude protein variety for the starter feed. Not many exotic vegetable protein sources are available, except for dried distillers grains with solubles (DDGS), and canola (Canadian rapeseed) that is used in Canada and certain northern United States.

Regarding animal-derived ingredients, poultry byproduct meal has long replaced fishmeal, which is too expensive now and not as available as in the past, and of course meat and bone meal (beef and/or pork). This is because poultry integrators have a surplus of poultry byproducts from their slaughterhouses. As such, this ingredient (and poultry fat, too) has become a staple source of protein and fat (unless defatted) for broiler diets (and other animal feeds). Depending on its quality, the inclusion level can be higher, but here we opted for a conservative number to illustrate its use and presence only.

Downloadable PDF: Traditional US broiler starter feed formulation

The rest of the ingredients require little discussion. Perhaps, some exception can be made for the vitamins and trace minerals. First, the two premixes are always advised to be used separately, and almost always are used mixed together. At least, choline chloride — a very reactive vitamin — is now almost universally added separately. Whether one uses a constant level of premix(es) throughout the life of a commercial broiler, a separate premix for each phase, or a phase-down approach of a universal mix (such as shown here) depends on the nutritionist designing each program.

Finally, although a corn-soy diet contains enough natural choline, most nutritionists prefer to add a bit extra of this vitamin because established requirements are several decades old. Perhaps, the greatest need for this precaution is for the starter feed. Incidentally, poultry byproduct meal is a super-rich source of choline (more than 6,000 ppm compared with about 500 ppm in corn).

In this set of formulas, antibiotics and anticoccidials are included, but their exact inclusion rate depends on manufacturer instructions. The inclusion rates indicated, also in the case of additives, are nothing more but a placeholder. Regarding all other additives, the most common additive that could have been used in this type of formula is phytase, something that could be explored in another set of formulas designed to illustrate this specific concept. Then, of course, each nutritionist has a specific array of additives that prefers to use.

Downloadable PDF: Traditional US broiler grower feed formulation

Notes on nutrient specifications

In order to round up the ingredients, to show easily how their concentrations decline gradually (except for corn, which always takes up any slack in formulation space) as birds grow, nutrient specifications have been allowed to deviate by relatively small fractions. In fact, this is often the decision of the nutritionist; that is, whether to prepare the final (production) formula on exact nutrient levels or rounded up ingredient figures to accommodate the needs of the feed plant.

For example, in many feed mills, corn cannot be weighed in increments of less than 5 kg.

In general, nutrient specifications also decline (except for energy) as birds grow heavier and, in fact, they can be made to differ for birds housed by sex, as females and males have different growth rates, hence different nutrient requirements. In the case at hand, we opted for relatively conservative energy and protein levels to reflect modern practice (even though antibiotics are being used in this case).

This is to avoid the sudden-death syndrome of heavy birds due to overeating, and a host of other metabolic disorders associated with rapid ingestion of nutrients and energy early in life. Nevertheless, the protein profile has been kept constant (some nutritionists will have a different opinion, but this is a simple exercise and not a commercial or scientific project), whereas the absolute amino acid levels have been kept quite high (even for the most demanding genetic lines).

A question can be raised regarding the dietary electrolyte balance, as some nutritionists might prefer a higher number, but this is refined nutrition beyond the scope of this discussion. Finally, other nutrients, such as linoleic acid, arginine and other amino acids could have been monitored, but given the commonality of the ingredients, it is rather assured that such secondary issues are sufficiently covered.

As a side note, it should be reminded that even when we formulate on exact nutrient levels, laboratory analyses invariably fail to return such exact numbers. This is because actual ingredients are not always as we describe them to the formulation program, and even laboratory analyses have their own acceptable degree of error.

This is why many nutritionists do not worry about a point up or down but insist on certain ingredient levels. This might make feed a bit more expensive, but it ensures animal performance in the absence of a vigorous analytical program. All of these will be discussed elsewhere.

Downloadable PDF: Traditional US broiler finisher feed formulation

Notes on feeding

These formulas have been designed for a feeding program lasting 42 days from hatching until market, which is the most common program worldwide — at least for the year 2020.

A final withdrawal feed is not included here as it is a local decision. Quite frequently for such feed, the finisher is used without the antibiotics and coccidiostats. The withdrawal period is determined by the veterinarian and the processing plant to ensure compliance with applicable laws and regulations.

Otherwise, this is can be quite a flexible program that can be modified in several ways. The most frequent one is that of 1-2-3 weeks, meaning the starter is fed for one week, the grower for two weeks, and the finisher for three weeks — for a total of six weeks or 42 days. Or, another more expensive variation is that of 2-2-2 (two weeks for each feed), but this is used only when the birds receive a super pre-starter during the first four days post-hatch, so the starter, if fed, for only 10 days.

Adjustments are required and are made frequently based on chick quality, season, feed quality and animal health.

Finally, the holding size of a feed silo that serves each broiler house plays an important role. Birds consume a known (more or less) amount of feed each day and, based on this number and the capacity of the silo, one can determine how much of each feed should be ordered and fed to each broiler house to roughly coincide with the required feeding days. Of course, matters are easier when operation size increases, but then other problems of logistical nature arise.

Table of Contents

In 2020, WATT Global Media and Ioannis Mavromichalis, Ph.D. published a series of animal feed formulas as a general information resource material. These formulas are not complete, but the exclusions, such as additives and vitamin/mineral premix specifications, are either covered in other publications or will be published in the future as part of this library of feed formulas.

Layer feed formulations and analysis

The article acts as a guide to describe Mavromichalis’ approach to the development of the series and frames how to use the information found throughout.

General: How layer feed formulas for U.S. white and EU red layers were created

Each installment of the layer feed formula installment includes analysis and sample formulations for typical layer diets for both U.S. white and EU red hens during both the development and production phases of the life cycle. In total, there are 12 formulas.

- Feed formulations for white US layers in the development phase

- Feed formulations for US white layers in the production phase

- Feed formulations for EU red layers in the development phase

- Feed formulations for EU red layers in the production phase

Swine feed formulations and analysis

This article acts as a guide to describe Mavromichalis’ approach to the development of the series and frames how to use the information found throughout.

General information: How the swine feed formulations were created

Each swine feed formulation feature includes analysis of the defined diet and includes sample formulations for different points in a pig’s life cycle: nursery/young pigs, grower-finishing and breeding.

- Piglet feed formulations

- Common US grower-finishing pig feed formulations with corn, soybeans and DDGS

- Breeding pig feed formulation commonly used in US diets

Broiler feed formulations and analysis

This article acts as a guide to describe Mavromichalis’ approach to the development of the series and frames how to use the information found throughout.

General information: How the broiler feed formulas were created

Each separate broiler feed formulation feature includes analysis of the defined diet and includes sample formulations of rations at different points in the life cycle of the broiler chicken: starter, grower and finisher.

- Traditional US broiler feed formulations with corn, soybean meal and poultry meal with antibiotics

- All-vegetable US broiler feed formulations with corn and soybean meal without antibiotics

- Modern European broiler feed formulations with wheat, soybean meal, rapeseed meal & fish meal without antibiotics

DISCLAIMER: All information under the section of Animal Feed Formulations Library is provided only as an information resource. It is not to be used or relied upon for any academic, commercial, public, private or other purposes. This information is not intended to be education for students or any other professional and does not create a student-mentor relationship. This information is not intended to be consulting for private or public entities and persons and does not create a client-consultant relationship. This information should not be used as a substitute for professional advice. Please consult with your local nutritionist, extension professional, feed representative or specialist, veterinarian or animal science technician before making any nutrition related decisions or for guidance about any specific nutritional or other issue.

Ioannis Mavromichalis, Ph.D., WATT Global Media and their owners, affiliates and employees shall have no liability for any damages, loss, injury, financial or animal performance and results, or liability whatsoever suffered as a result of your reliance provided in this section, even after your consulting with your advisers.

Contacts:

For comments, questions or suggestions, please contact Ioannis Mavromichalis, [email protected], or Feed Strategy's editor Jackie Roembke, [email protected].