All-vegetable US broiler feed formulations

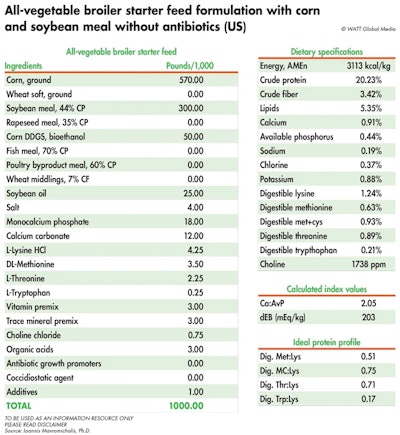

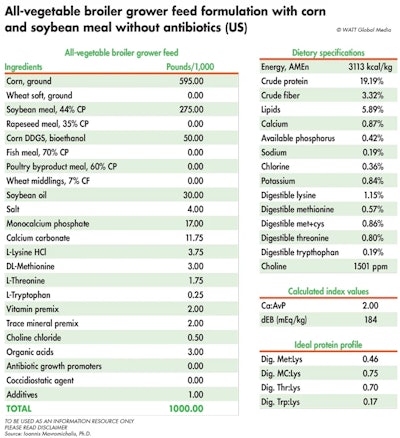

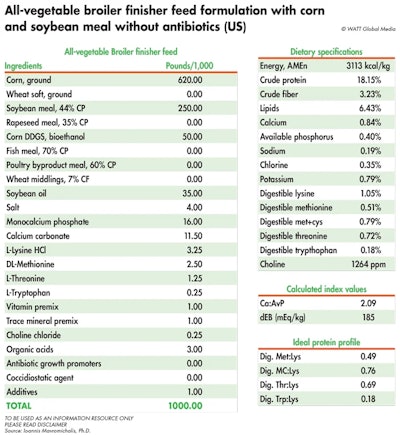

The second set of formulas (BR02) in the Animal Feed Formulations Library describes the modern trend in broiler feed, that of a vegetable diet with corn and soybean meal without antibiotics and coccidiostats.

Before engaging in the following notes, it would be advisable to review the relevant notes of the BR01 broiler feed formulas set, which is similar and considers the use of antibiotics and coccidiostats. In the present discussion, we will consider only the step taken to account for the absence of these two medications, and of course the replacement of the animal protein used in BR01 with a vegetable one.

Downloadable PDF: All-vegetable US broiler starter feed formulation

Notes on ingredients

Most notably, we have removed the poultry byproduct meal and replaced it with another protein source, common in the U.S. Of course, we could have just increased the inclusion of soybean meal, the use of feed-grade amino acids, or even bring in canola. However, the U.S. market has been flooded with bio-ethanol corn byproducts (corn dried distillers’ grains with solubles or DDGS). For this reason, we considered the inclusion of DDGS more probable than any other source of protein, but there were a couple of other reasons.

First, we did not want to increase the level of soybean meal in the starter feed above that of 30% in the starter feed as many nutritionists now consider that too much soybean meal contributes too many anti-nutritional factors in the early phase of life of the chick. We also wanted to keep things simple and similar between the two sets (BR01 and BR02) as they refer to the same market.

And, finally, we wanted to bring in DDGS as a moderate source of fiber as this nutrient (or feed component for some experts) is considered essential for gut health in the absence of antibiotics.

Lamentably, no real feed solution has been encountered in the case of removing the coccidiostats. Although they are referred to as antibiotics in the United States, they attack protozoa and not bacteria, which are the targets of what we know as antibiotics.

Minor adjustments were made to all other ingredients to reflect the nutrients not covered by DDGS as it contains only 25-30% crude protein as opposed to 60% in poultry byproduct meal, slightly less energy, and considerably less choline. As such, feed-grade amino acids have been proportionally increased, and extra soy oil and choline chloride were added. Other minor adjustments to minerals were warranted, but these were simple enough to consider.

What is of importance to note is the introduction of organic acids. Here, we opted referring to this class of ingredients/additives without pointing to any particular acid. Many use a form of non-offensive butyric acid, but others object to its exorbitant price and prefer to use a blend of other acids.

Nutritionists rarely agree on which organic acid or blend is best as each one has different experiences and opinions. What most agree, however, is that industry inclusion levels of 1-2 kg per metric ton are rather inadequate for most cases, preferring a more robust dosage of 5 to 10 kg per metric ton. Others prefer to keep a low inclusion level and combine organic acids with other additives, such as probiotics, yeasts, phytogenics and more products than could possibly one remember. Again, it remains a personal preference what to use.

Downloadable PDF: All-vegetable US broiler grower feed formulation

Notes on nutrients

We kept the same conservative numbers on energy (roughly 3000, 3050, and 3100 kcal/kg AMEn for the starter, grower, finisher, respectively), but we lowered by roughly two percentage points (from 22% to 20% in the starter and so on) the crude protein level. This was done to deprive gut pathogenic bacteria from excess (non-digested) protein on which they thrive.

More aggressive cuts are possible, but then we need to monitor more amino acids. In fact, to maintain bird performance, we did not alter the concentration of amino acids (as nutrients) as we increased that of the feed-grade amino acids (as ingredients). This is common practice favored universally by all nutritionists, unless frowned upon by their markets.

In the case of minerals, only salt (sodium) was lowered slightly, again as common practice in antibiotic-free formulas, to minimize the incidence of osmotic diarrhea (water leakage in the gut). This kind of water leakage is not pathogenic per se, but it can lead to secondary pathogenic complications, and of course to increased litter moisture. In fact, the latter problem can also occur in antibiotic-based programs, and in those cases the level of sodium is controlled quite often too severely.

In this set, the dEB is more acceptable as chlorine (negative) has been lowered and potassium (positive) has increased again slightly. Roughly we target a level around 200 mEq/kg, but opinions can be quite variable, as we are not even sure what is the meaning of this index.

Lastly, the ideal ratio of calcium to available phosphorus at around 2.0 has remained with the adjustment of calcium carbonate and monocalcium phosphate. Here, it should be noted that limestone is not the same as pure calcium carbonate, and that dicalcium phosphate is another common source of phosphorus.

In the case of fiber, the introduction of DDGS has increased crude fiber concentration by about 0.25 percentage points, which is barely enough. In cases of diarrhea, some more aggressive form of fiber is used, namely soy hulls or wheat bran, but that is a special case and does not conform to the requirements of the present discussion.

Fiber and energy are working in opposite directions and, without energy, birds do not grow as fast as we want them to. So, in broilers, adding high amounts of fiber is not as routinely exercised as in other species — unless there is a history or a sudden outbreak of diarrhea.

Downloadable PDF: All-vegetable US broiler finisher feed formulation

Notes on feeding

The same notes as those included under BR01 are applicable here, too. The use of a super pre-starter is even strongly advocated when antibiotics and anticoccidials are not used, but cost is often prohibitive, although results are invariably in favor of improved animal performance and reduced mortality and morbidity.

Table of Contents

In 2020, WATT Global Media and Ioannis Mavromichalis, Ph.D. published a series of animal feed formulas as a general information resource material. These formulas are not complete, but the exclusions, such as additives and vitamin/mineral premix specifications, are either covered in other publications or will be published in the future as part of this library of feed formulas.

Layer feed formulations and analysis

The article acts as a guide to describe Mavromichalis’ approach to the development of the series and frames how to use the information found throughout.

General: How layer feed formulas for U.S. white and EU red layers were created

Each installment of the layer feed formula installment includes analysis and sample formulations for typical layer diets for both U.S. white and EU red hens during both the development and production phases of the life cycle. In total, there are 12 formulas.

- Feed formulations for white US layers in the development phase

- Feed formulations for US white layers in the production phase

- Feed formulations for EU red layers in the development phase

- Feed formulations for EU red layers in the production phase

Swine feed formulations and analysis

This article acts as a guide to describe Mavromichalis’ approach to the development of the series and frames how to use the information found throughout.

General information: How the swine feed formulations were created

Each swine feed formulation feature includes analysis of the defined diet and includes sample formulations for different points in a pig’s life cycle: nursery/young pigs, grower-finishing and breeding.

- Piglet feed formulations

- Common US grower-finishing pig feed formulations with corn, soybeans and DDGS

- Breeding pig feed formulation commonly used in US diets

Broiler feed formulations and analysis

This article acts as a guide to describe Mavromichalis’ approach to the development of the series and frames how to use the information found throughout.

General information: How the broiler feed formulas were created

Each separate broiler feed formulation feature includes analysis of the defined diet and includes sample formulations of rations at different points in the life cycle of the broiler chicken: starter, grower and finisher.

- Traditional US broiler feed formulations with corn, soybean meal and poultry meal with antibiotics

- All-vegetable US broiler feed formulations with corn and soybean meal without antibiotics

- Modern European broiler feed formulations with wheat, soybean meal, rapeseed meal & fish meal without antibiotics

DISCLAIMER: All information under the section of Animal Feed Formulations Library is provided only as an information resource. It is not to be used or relied upon for any academic, commercial, public, private or other purposes. This information is not intended to be education for students or any other professional and does not create a student-mentor relationship. This information is not intended to be consulting for private or public entities and persons and does not create a client-consultant relationship. This information should not be used as a substitute for professional advice. Please consult with your local nutritionist, extension professional, feed representative or specialist, veterinarian or animal science technician before making any nutrition related decisions or for guidance about any specific nutritional or other issue.

Ioannis Mavromichalis, Ph.D., WATT Global Media and their owners, affiliates and employees shall have no liability for any damages, loss, injury, financial or animal performance and results, or liability whatsoever suffered as a result of your reliance provided in this section, even after your consulting with your advisers.

Contacts:

For comments, questions or suggestions, please contact Ioannis Mavromichalis, [email protected], or Feed Strategy's editor Jackie Roembke, [email protected].